Durable Thermal Insulation and Noise Reduction Roofing Sheet

INTRODUCTION:

Do you have the following concerns before building a new house with color steel plates?

The color steel plate material is fragile, and the life of the house is short; or neither is it resistant to cold in winter, nor resistant to heat in summer; or the noise outside makes you unable to sleep in the middle of the night l, and even affects your daily life, etc. If you are facing these kinds of troubles, please don’t be worry, because Zhongtuo will help you, giving you a much cozier house–more durable, anti- condensation, thermal insulation, and without any noise. Come here and see a new roofing sheet.

ADVANTAGES:

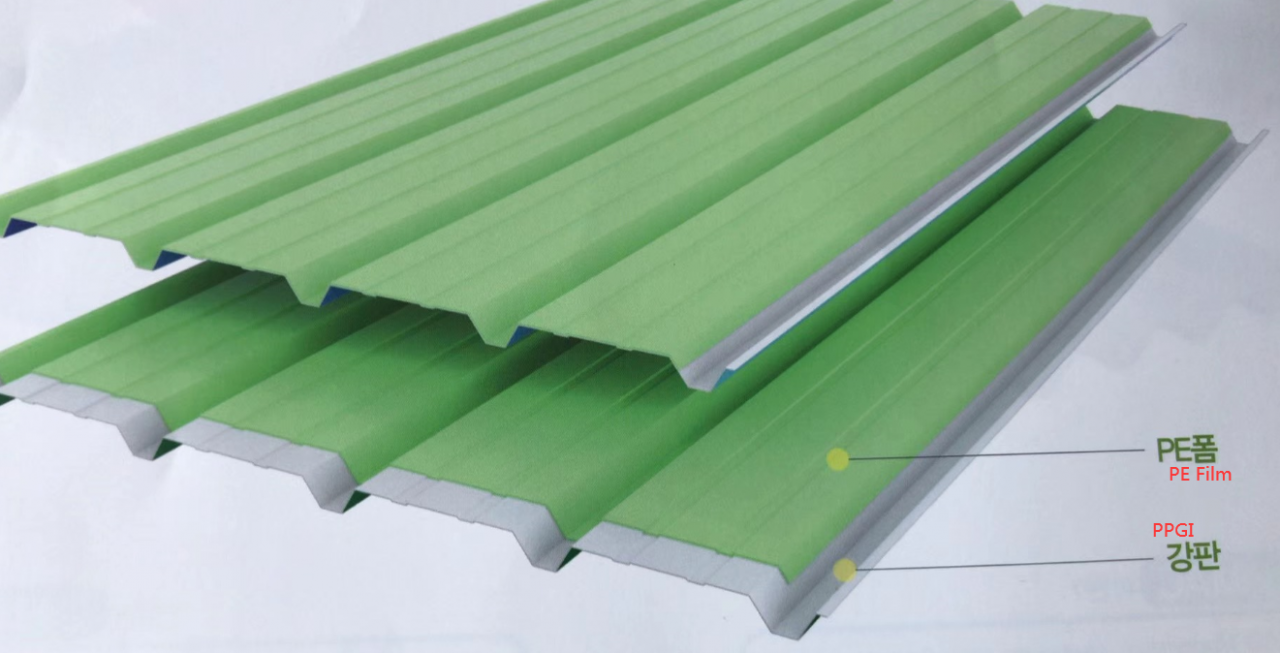

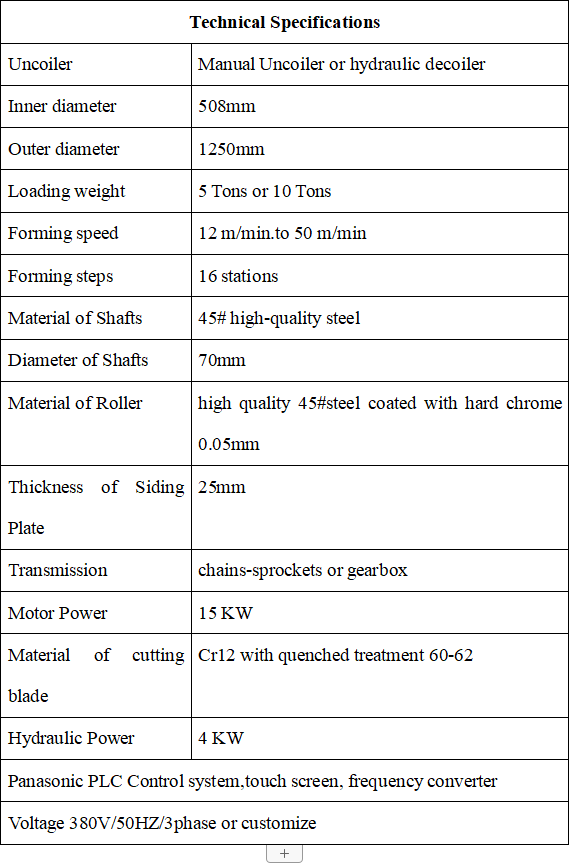

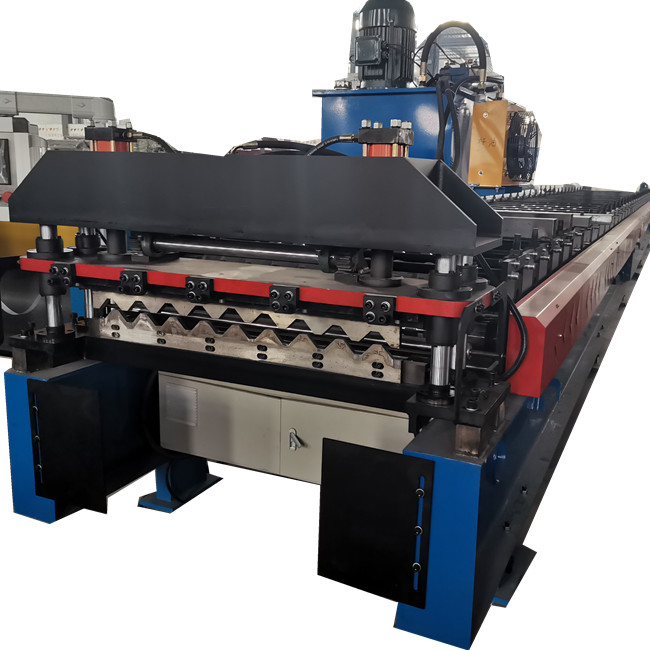

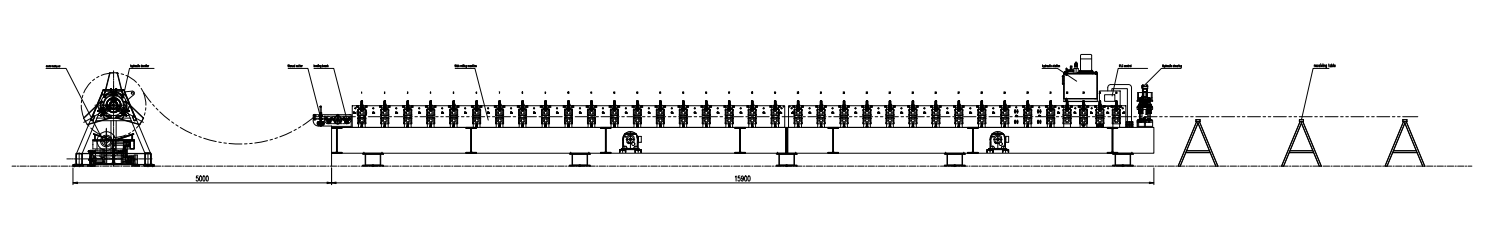

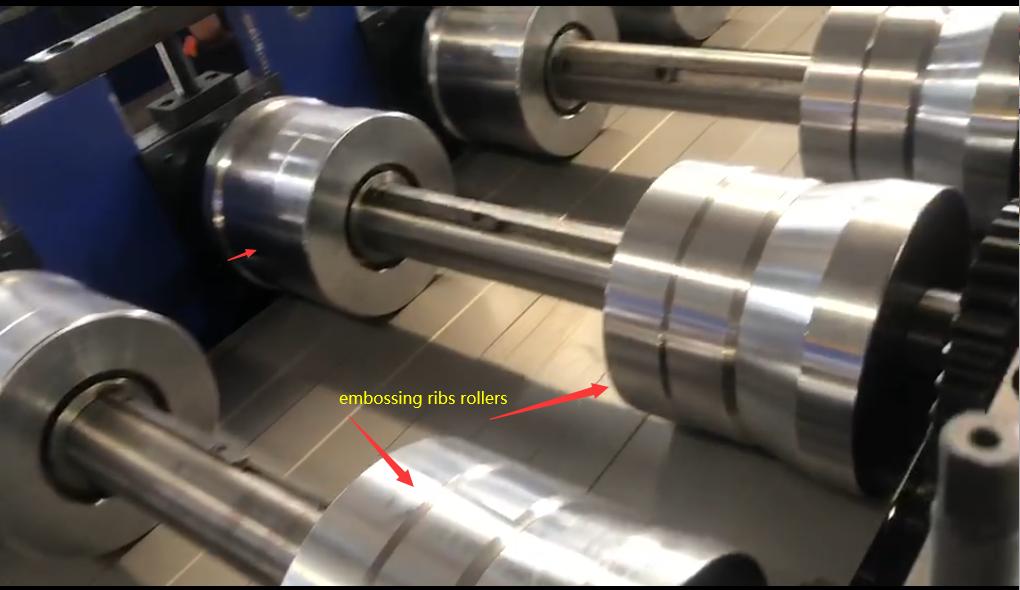

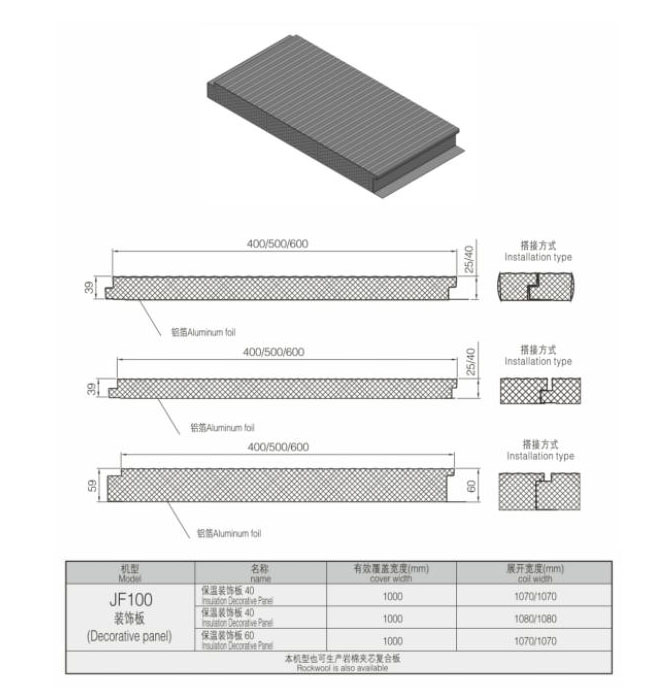

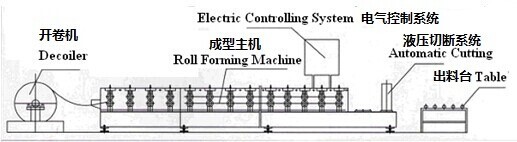

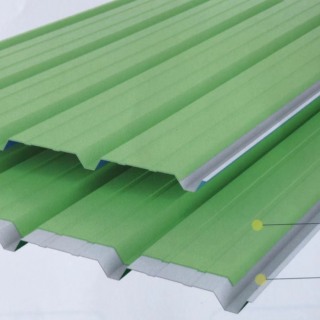

This kind of sheet is made of a new type of thermal cladding material, which is composed of up to 8 layers of materials, and is processed through five high-temperature heat bonding processes and two high-strength anti-aging glue bonding processes. So compared others, your house will last longer and be more resilient to disasters.

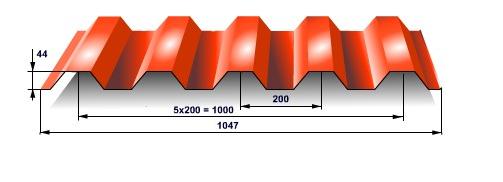

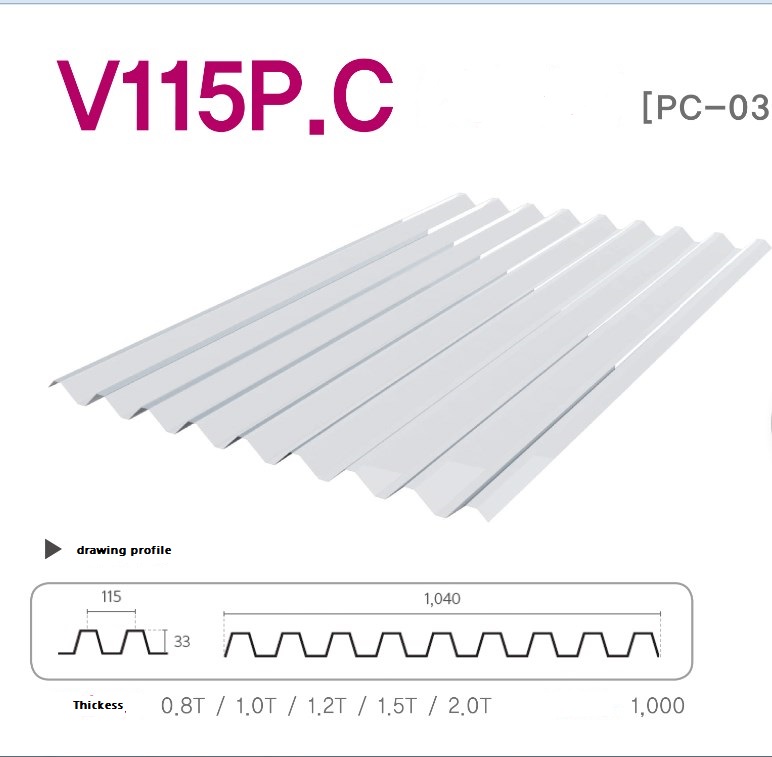

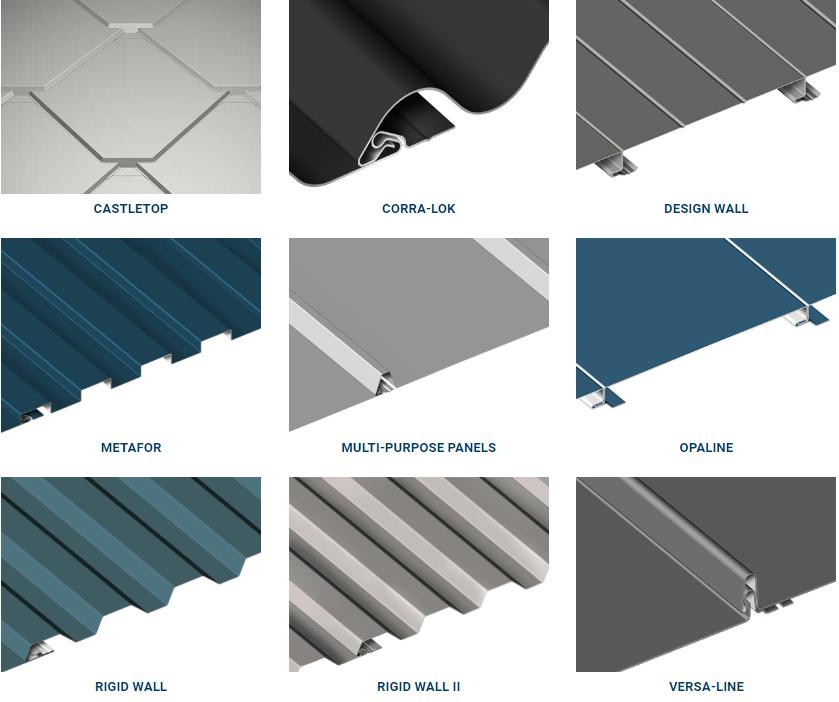

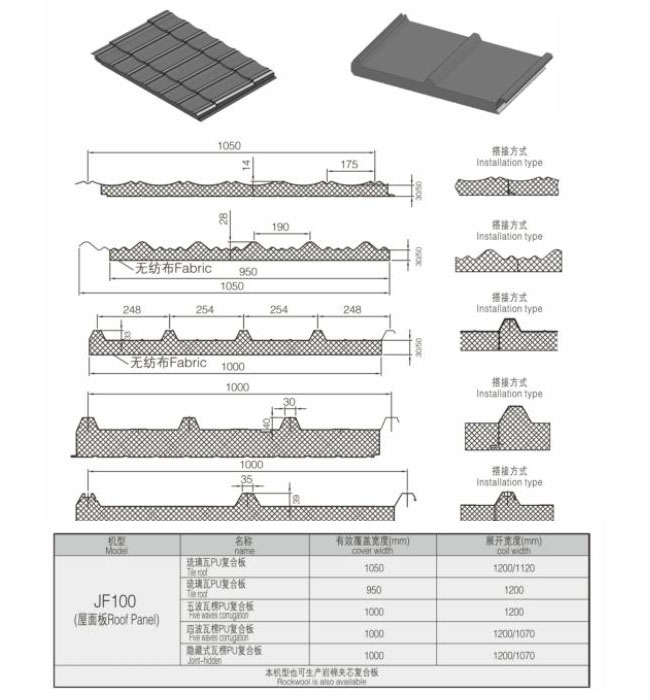

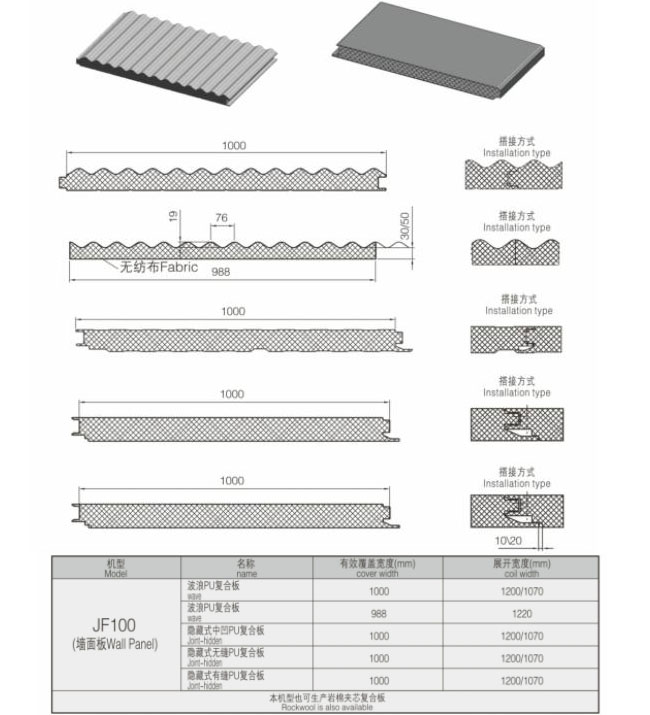

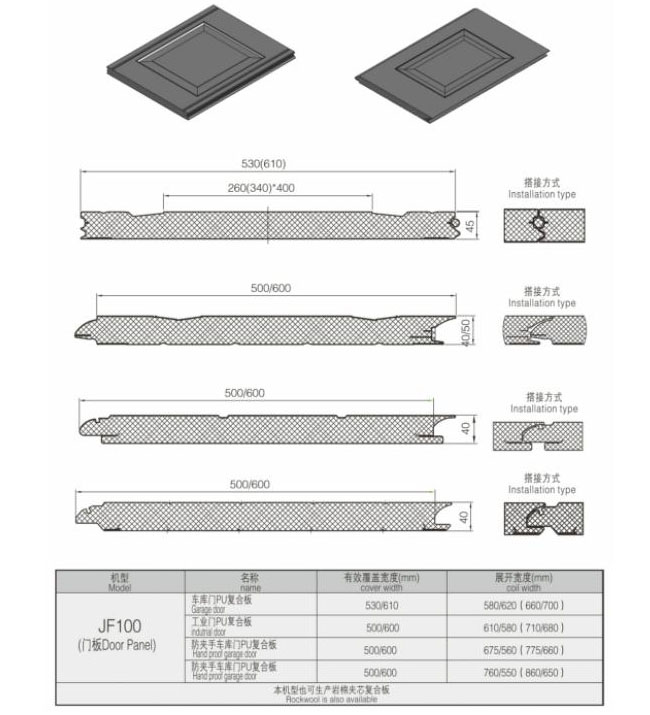

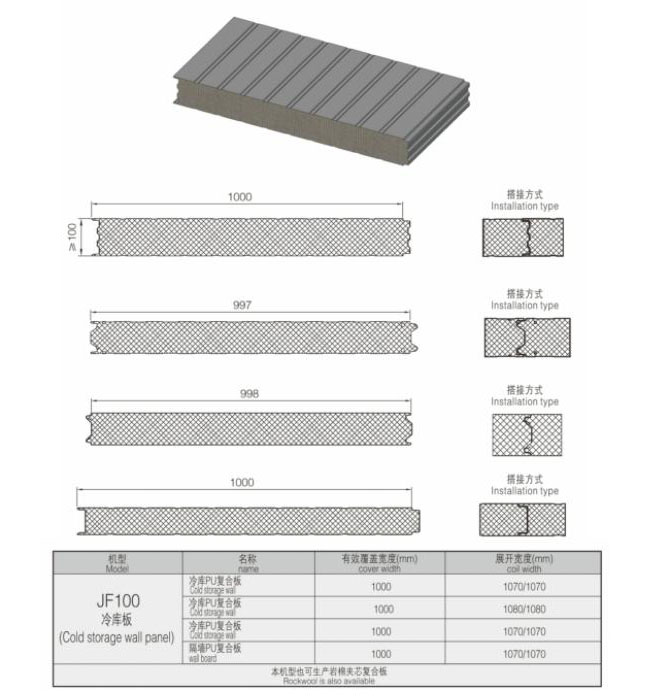

In addition, we also take the climate into consideration. During winter, the big difference of temperature between day and night is easy to cause condensation. If not considered in the sign stage, condensation will greatly reduce the life of the building and affect the functionality, so the cost of maintenance will increase significantly. Anti-condensation sheet is dedicated to solve these problems in metal buildings, which could replace insulation materials, with more than20 years’ life expectancy, reducing construction costs and easy to pass fire protection approval. On this basis, Zhongtuo designed the new material and metal type roofing sheet. This new type roofing sheet,can be customized as the shape of roofing sheet you need,and compared to the normal PPGI metal roof sheet, It is better in terms of lifetime and muti-function.

More importantly, for corrosion of large industrial plants and warehouses (coking plants, ammonium sulfate plants, metallurgical plants, vulcanization plants, pickling plants, battery plants, chemical plants, steel rolling plants), the requirements for the acid and alkali resistance of the building are very high, fortunately, we can meet such a request. The roofing sheet we provided have strong acid and alkali resistance, escorting your production and operation.

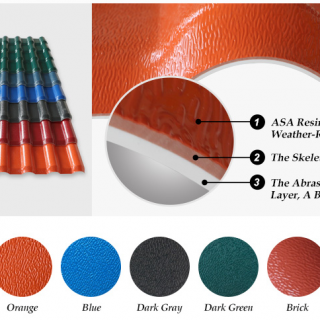

So compared with other ordinary color steel plates, its advantages are more prominent, and since the this kind of sheet was promoted in the market, it has also been widely praised by users with its super anti-corrosion performance heat insulation effect, long service life, sound insulation and super strong acid and alkali resistance capability.

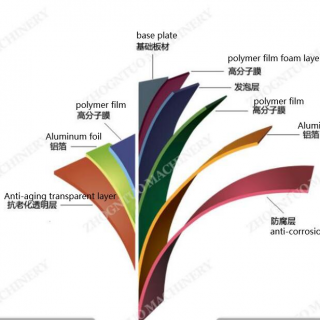

A house with this sheet can not only ensure a good quality of life, but also save the cost of repairing the house. It will definitely be a very wise choice to cooperate with us. Here more for your reference. If you need just contact us and tell \us your prefer, our products can be customized into different shapes and colors according to your like.

If you are interested in our products, please contact us.