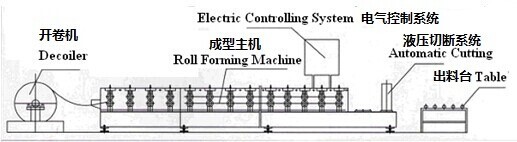

Machine parameters

3T Manual/hydraulic decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system.

Note: You can choose the manual decoiler or the hydraulic decoiler as need. The price of the hydraulic decoiler is 3500USD higher than the manual one. If you want the loading car, you need to pay more 2000USD.

- Max coil inner diameter: 450-550mm 2 max loading capacity: 3T

- Max width of coil: 1000mm

- Hydraulic power: 3 kW

Pump diameter: 120mm

Main Roll Forming Machine

Door frame roll forming machine

- Feeding and leveling part

Putting the raw material through the platform for manufacturing and processing, can ensure the products are clean, parallel and everything is uniform. Consult the equipment regulation for the function of locating the iron panel.

- Roll forming

After leveling, the steel plate will enter this part for forming. Voltage: 380V/50HZ 3Phase (as customer’s request)

Roller fixer : Guide column Frame: pillar frame Memorial arch frame type Frame thickness: 25mm Drive mode: gear

Material of rollers: GCr15 Quenching treatment at 56 degree. Material of shafts: 45# steel with tempering

Diameter of shafts: φ90mm, adjusting density by harden, quenching. Number of stations: 16 stations

Main power: 2 x 5.5kw (two motors for transporting power more evenly.)

Hydraulic Shearing(Door frame roll forming machine)

- Shearing part

After roll forming, the product will be cut at this part. Material of blades: Gcr12 quenched

Power supply : hydraulic power

Stroke switch : non-contact photoelectric switch

- Hydraulic station 46 # hydraulic oil 5.5kw hydraulic power

Components: The system includes one set of hydraulic tank, one set of hydraulic oil pump,

two hydraulic pipes, and sets of electromagnetism valves.

PLC control system

Door frame roll forming machine

Feature:

- Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and

- Other electric element are

- Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and

Note: if you do not like this type portable PLC, we can change to cabinet type.

Product receiving table

It adopts welded steel and supported roller to transmit the products.