FLOOR DECKING FORMING MACHINE - ZTRFM

Zhongtuo metal decking manufacturing lines

Steel decking roll forming machine

FLOOR DECK ROLL FORMING MACHINE

Floor deck is the plate which supports the floor concrete that is called the pressed steel plate, also called the floor bearing plate and the steel bearing plate. It has three types: Open floor deck-necked floor deck-closed floor deck.

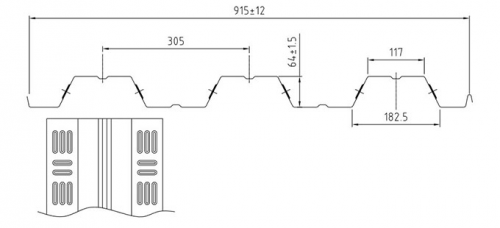

Open floor deck-Steel Deck Roll Forming Machine

In short,Roof decking floor profiles are typically used as the structural component. The steel decking floor is a cold-formed steel sheet. Metal Decking use in roof and floor systems for supporting the concrete or insulating membrane of a roof. Its design and construction magnify properties of the steel. It causes to create a high strength-to-weight ratio that lowers the material, handling, and erection costs.In addition to, Steel Floor decking roll forming machine

This is the new type we engineer for decking machine, used for building surface panel. Metal Deck Roll Forming Machine is a modern, pre-eminent solution for concrete floor work.We can design metal deck roll forming machine according to your drawing profile.

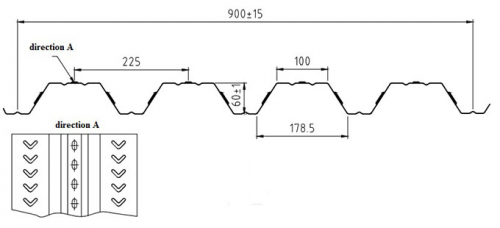

Necked floor deck–Steel Deck Roll Forming Machine

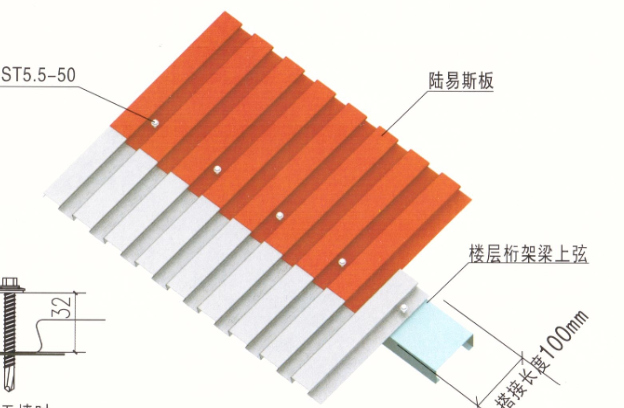

Necked floor deck–Steel Deck Roll Forming Machine, some place is also called ie as versa-Dek metal decking Machine. Versa-Dek metal decking is ideal for use in mid-rise residential structures. Dovetail system provides the thinnest total floor depth, reducing story height while maximizing ceiling height, with clear spans up to 28 ft. Versa-Floor is non-combustible and is fire-resistance rated up to four hours without protective coverings such as gypsum and spray-on materials.

Features of this type metal decking:

Also call it as dovetail profiled steel plate production line which is a new generation product recently launched by our company. This unique form of metal profiled plate is beautiful in appearance, easy to install, and has good mechanical properties and fire protection. Performance, suitable for any floor. For these two types of floor deck hanging accessories, the bottom of the floor deck is almost flat, and the narrow inverted dovetail mouth is very convenient for hanging. Such as suspended ceilings, water and electricity pipes and other equipment, without pre-burying, drilling, electric welding, etc., play a key role in the damage during construction and the integrity of the concrete.

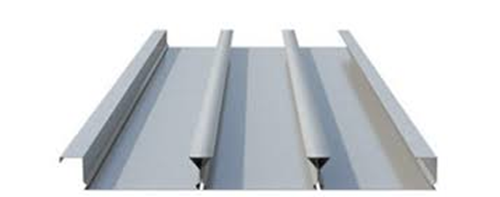

Closed type deck-Steel Deck Roll Forming Machine

Experiments have proved that it has stronger bearing capacity and shear resistance than other open floor deck systems. The special design of the closed rib shape allows the slab ribs of the steel bearing slab to be completely surrounded by concrete, just like the steel bars in the cast-in-situ slab, so as to maximize the respective characteristics of steel-concrete and successfully applied to the reinforced building. In the bearing system, it has excellent fire resistance.

Metal decking machine for villa house

Metal decking advantages

It is a kind of lightweight and high-strength profiled steel sheet formed by rolling and forming of 1250mm wide high-quality cold-rolled hot-dip galvanized steel sheet. It adopts a dovetail necking design with an effective width of 768mm and a wave height of 16mm.

Product advantages

- Reasonable structure

- Easy and quick installation

- Lightweight and high strength

- Low sheet loss

- Strong corrosion resistance

- Durable

- Wide range of applications

- green economy

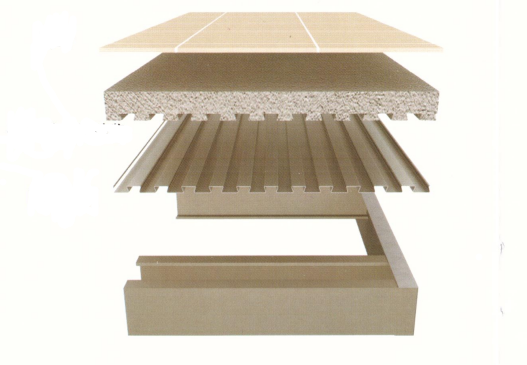

The use for villa house metal decking

- It is used as structural slabs, and a layer of dry hard cement mortar is laid on top;

- No leveling layer is needed on the board, and the dry hard cement mortar is directly combined with the surface layer.

- Low loading weight. As a light steel villa floor, compared with the traditional OSB board, the load on the board is reduced by about 30%.

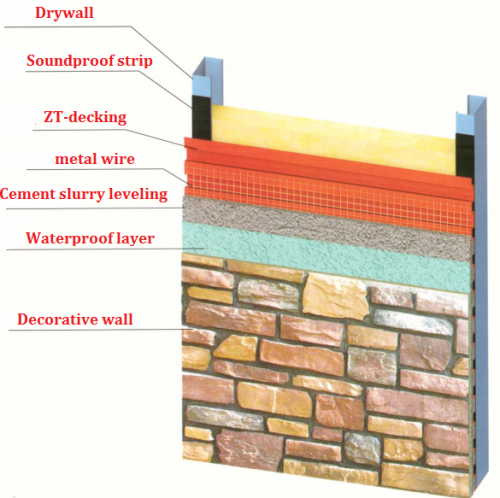

used as wall panel

- Paste a 2mm-thick sound-proof and vibration-damping strip on the light-steel keel column of the wall, sound-proof and vibration-damping strip with this decking, and fix it with self-tapping screws at the valley position;

- Install the hot-dip galvanized welded wire mesh close to ZT decking board, level the cement mortar, make a waterproof layer on the leveling layer, and then paste the culture stone or paint the real stone paint and other decorative surfaces (or directly install the imitation wood grain cement on the surface of the ZT decking Fiber pressure plate or metal embossing plate).

Advantages of using it as wall panel:

- Protect from termites

Compared with OSB board, its material property is steel plate, which is not corroded by termites. In southern areas where termites are frequent, it can effectively replace OSB board for external walls.

- Effectively prevent the whole falling off

Compared with other flat plates, the concave-convex groove structure can effectively engage with the cement mortar leveling layer, which greatly enhances its overall stability and prevents delamination.

3.Effectively prevent thermal expansion and swelling

The expansion coefficient is 1.2×10°/℃, which is slightly affected by temperature changes; its material is steel, which does not shrink and expand with moisture content, which can effectively control its deformation without stressing the light steel structure itself, nor due to Large deformation causes cracking of the leveling layer or surface layer.

Advantages of metal decking rolling forming machine

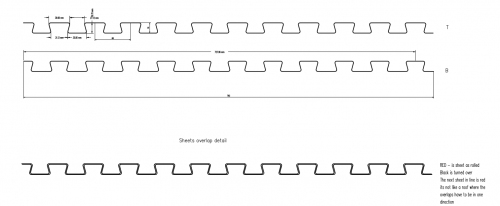

- ZT structural floor and facade rolling forming machine can produce the floor decking in the speed of 15 to 20 meter per minute.

- We can make the perfect shape when overlapping, it can match one and another easily.

- The machine we design using 43 roller stations to make sure the shape is good and fixed well.

- Machine we use 30mm thickness middle plate.

- Easy for installation, all electrical components we use the Simens Brand