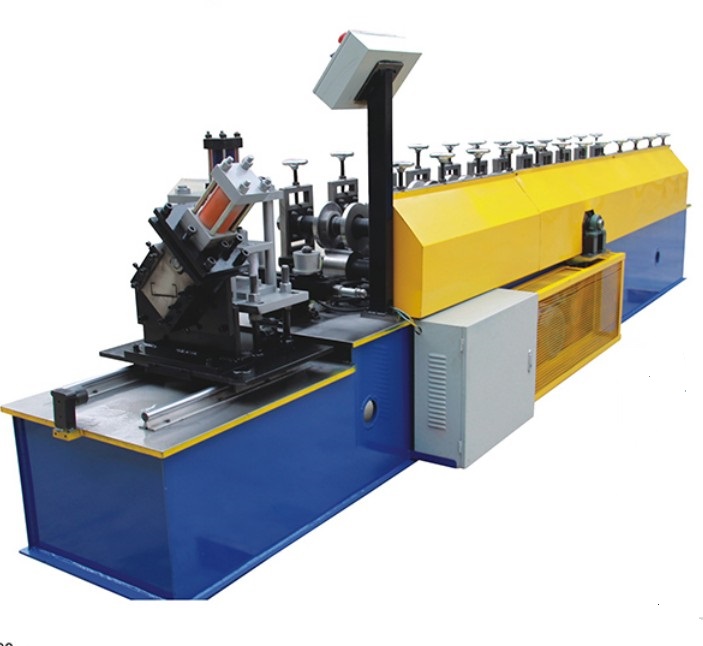

STUD&TRACK ROLL FORMING MACHINE - ZTRFM

Metal Stud and Track Roll Forming Machine is for produce studs and tracks with various types. Which is widely used in light steel construction industry.

Zhongtuo Stud and track roll forming machine

Zhongtuo metal stud and track roll forming machine offer builders a competitive alternative to traditional wood trusses.This machine provides significant improvements over other light gauge steel trusses currently available.

Our machine could update with the fashio for providing new design increases material efficiency, ease of fabrication, simplicity of erection, and improved safety of material handling.

Our machine could update with the fashio for providing new design increases material efficiency, ease of fabrication, simplicity of erection, and improved safety of material handling.

Stud and track roll forming machine

Metal Stud and Track Roll Forming Machine

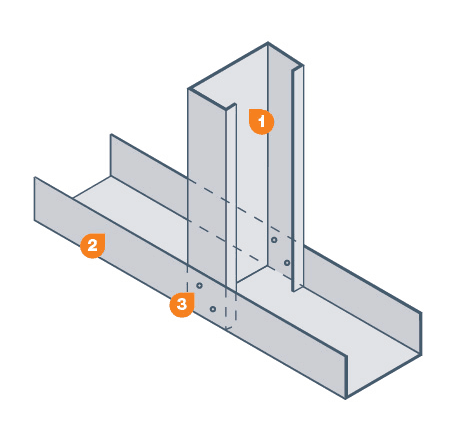

What’s Stud and Track?

The stud and track are very easy to install with the minimum of knowledge and tools. The studs fit vertically into the suitable sized track that is fitted horizontally at the top and bottom.

The Layout of Stud and Track Machine

Uncoiling–Feeding and Guiding–Roll Forming– Straightening– Cutting– Collecting

- Uncoiler

- Roll Forming Mill with Straightener

- Cutoff Unit

- Receiving Table

- Controlled box

Machine Components and Specifications

3 Ton Electric Uncoiler

- weight: 2TON

- D of Coil: 460-560mm

- Steel Plate and C beam welded

- Function: The uncoiler is used to hold and uncoil the coils. This manual uncoil is unpowered. You need to manually adjust the uncoiler mandrel to tension the coil

Feeding and Guiding Device of Stud and Track Machine

- Width Range:200-300mm

- Feeding Type: Manual feeding

- Guiding Type: Manual adjust

- Function of Guiding: Avoid the deviation of the material

Metal Stud and Track Roll Forming Machine

- Machine Structure: The main base use C beam welded, assemble the driven motor inside of the machine, the mill structure use whole plate welded, bottom bearing block assemble in the steel plate directly which is same as Taiwan design

- Forming Speed: 12-15m/min

- Machine Voltage and Frequency:415V, 50Hz, 3Phase

- Material of Rollers: GCR15, CNC processing, HRC58-62, chromed 0.05mm thickness

- Forming Steps:18

- Material of Shaft: ASTM1045, lathe process and polish the out diameter

- Diameter of shaft: 60mm

- Material of Spacers: ASTM1045, wall thickness: 8mm, chromed and hardness treatment.

- Driven Motor: Chinese Guomao Brand, 5.5KW

- Transmission: By gears

- Machine Side Wall Panel:18mm

Hydraulic Cutting Device

- Cutting Type: Hydraulic cutting, roll forming part stop when cutting

- Hydraulic Motor Power:4KW

- Hydraulic Working Pressure: 12-16Mpa

- Material of Cutting Blade: Cr12 with heat treatment

- Length measuring: Automatic encoder(Omron Brand) length measuring

- Tolerance of Length: ±1.0mm

Controlled System for Metal Stud and Track Machine

- Operating System Language: English and Chinese (If you need other language, we will send you the Instructions of English Version, and you please translate the instructions into the language you use. Then we will set the Instructions of your language for you.)

- Voltage and Frequency: 415V, 50Hz, 3Phase

- Control Panel: Touch screen with button-type switch

- Unit of Length: Millimeter (switched on the control panel)

- PLC Brand: Panasonic

- Frequency Converter Brand: Yaskawa

- Encoder Brand: Omron

- Touch Screen Brand: MCSG

- We adopt aviation plug for easy joint the wires by customers.

- You can set the cutting length and quantity on the touch screen. The machine will automatically stop after the completion of the cutting program.