STEEL SLITTING MACHINE - ZTRFM

Zhongtuo steel sheet slitting line

Steel slitting with cut to length machine

Steel Slitting Machine Line

What’s Slitting Machine Line?

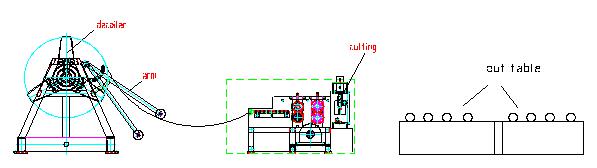

Slitting is the operation of cutting a wide strip into a number of narrow strips by passing the strip between circular cutters or blades. Slitting lines consist of an uncoiler for holding the wide coil, one or more slitters, and a coiler for simultaneous recoiling of all the slit strips.

Suitable Coil Material

- Stainless Steel Coil

- Galvanized Coil

- Galvalume Coil

- Prepainted Galvanised Steel

- Prepainted Galvanlume Steel

- Aluminium Coil

- Copper coil

- Low Carbon Steel Coil

- Silicon Steel Coil

Mother Coil Data

- Thickness Range: 0.2-2.0mm

- Width: 400-1600mm

- Coil Weight: Max 20 Ton

- I.D of Coil: 508-610mm

- O.D of Coil: Max 2000mm

Son Coil Data

- Slitted Width: 20mm Min

- Width precision: 0.05mm

- Slitting Bur: 0.05mm minimum

- Recoiling Looseness: less than 2mm

- Slitting Number: 25 Pcs Max

Slitting Line Specifications

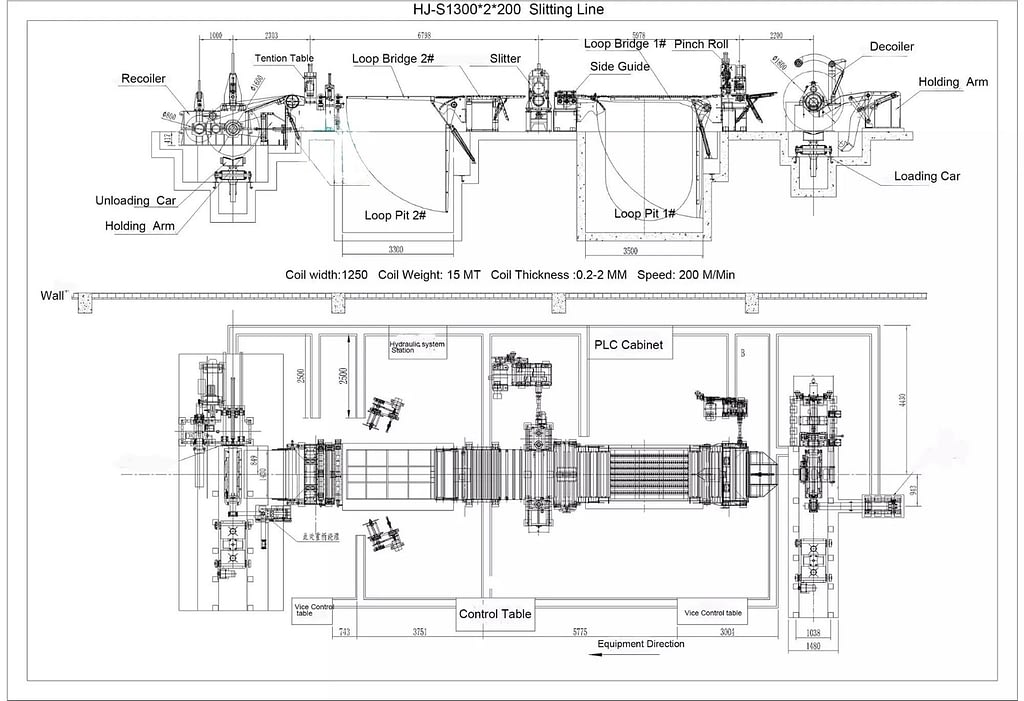

Machine Components

- Loading Coil Car

- Decoiler

- Straightener device(optional)

- Head Shear /Pinch roll/(optional)/Film Device(optional)

- Bridge/Loop pit

- Side guide

- Slitter

- Side Guide & scrap winder

- Bridge /Loop pit

- Separator &Tension station

- Recoiler and Support Arm

- Unloading coil car

- Hydraulic system

- Pneumatic System

- 15.Electronic Controller( PLC ,Control Table)

Brief Introduction of Slitting Machine Components

1: Coil Car

Loading coil into decoiler’s arm. moving in rails, lift up and down power from cylinder, v type saddle.

2: Hydraulic Decoiler

Hold coil and open it ,feeding to next step.

- Drum up shrink range: 465-30 to 520 mm

- Drum increases and the hydraulic cylinder ROBFA – 200 * 100

- Spindle is made of 40 cr solid round steel by rough turning, conditioning

3: Pinch Roll

The pinch roll is for pinching the head into loop bridge.

4: Loop Bridge

Keep enough Coil in pit loop so the line can work well, and make each part’s speed in little difference.

5: Main Slitter

Slit the coil sheet into strips. It consists of main steel base, two support stands , slitting shaft, slitting blades and hydraulic cylinders. Hydraulically pushing one stand makes replacing the slitting blades easy and quick.

6: Scrap winder

Scrap winder is a very economical device for slit scraps. There are two types of scrap winder. One is winder set on sides of the conveying table. Another is set on two sides of the line.Separator &Tension station.

7: Separator &Tension station

It include separator shaft and separator disc. And will ensure the strips smoothly going into the tension station. The tension roller press tightly for perfect recoiling

8: Recoiler and Support Arm

Recoiler is consisted of steel base, support arm, recoiling shaft and pressing arm. This press arm shaft assembled with separator discs which hydraulically follow the material during recoiling to ensure the strips recoiling straightly.