C CHANNEL ROLL FORMING MACHINE - ZTRFM

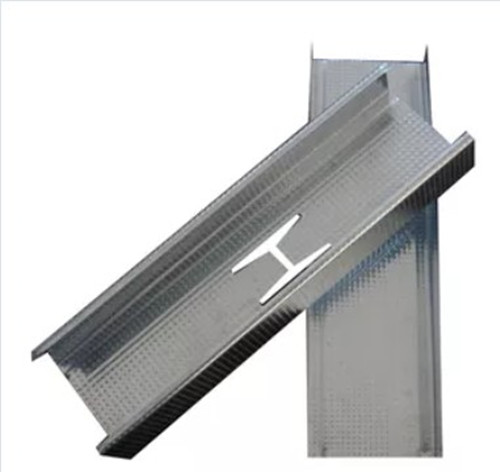

Zhongtuo c channel roll forming machine

C channel rolling forming machine

Automatic C channel steel roll forming machine

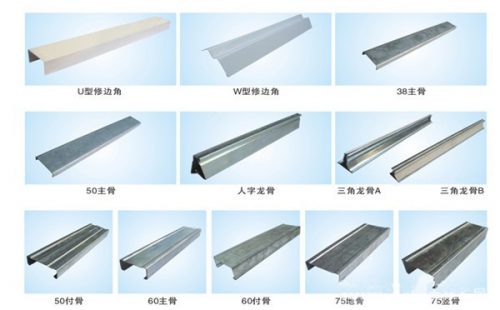

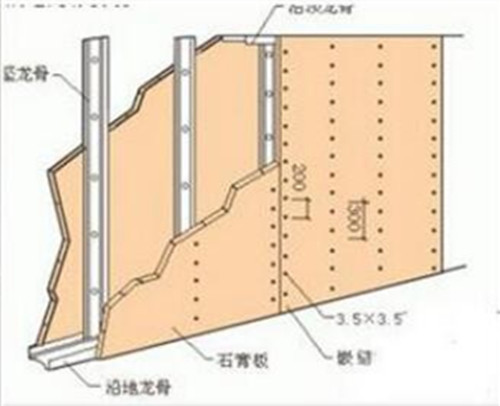

Automatic C channel steel roll forming machine is weldly used in the celling and drywall construction. Compared with cement construction and wooden construction,

Steel frame is more light and durable.Thanks to these advantages, C/U/Omega stud is welcomed in construction field.

Advantages of our Automatic C channel steel roll forming machine

- High speed.Our high speed C/U/Omega stud roll forming machine speed can up t0 80m/min.

Normally, C/U/Omega stud roll forming machine’s speed is around 45m/min,

- High durable. high speed C/U/Omega stud roll forming machine adopts cast steel roller fixer.

- High automatic. high speed C/U/Omega stud roll forming machine adopts PLC systerm.

User can set production quantity, production speed on control cabinet.

Working process:

Decoiler–feeding–roll forming–punching(if need holes or logo)–cutting–product table

Technical parameters for the whole production line:

1.Manual decoiler

Capacity:1.5T

Coil inner diameter:350-450mm

Coil width:300mm

2.Roll forming machine

1)machine structure:cast iron roller fixer

2)Main power:5KW siemens motor

3)Forming stations:12 stands

4) Way of drive:by gear

5)Diameter of shaft:50mm

6)Max rolling speed: 45m/min

7)Thickness: 0.3-0.8mm galvanized steel or prepainted sheet,G550Mpa

8) Material width:100mm~300mm

9)Material of roller:CR12 with quenched treatment

10)Material of blade mould:Cr12, quenched 58-62

11)way of cutting:hydraulic mould cutting(flying cut,cut without stop)

12)Length cutting tolerance:+/-1.0mm

13) Electrical requirement:380V,50Hz,3P

3.Control system

1)Control system:PLC

2)PLC brand:Delta

3)Screen:Touch screen

4)Screen brand:Touch screen

4.Hydraulic system:

1)Hydraulic pressure :16Mpa

2)Hydraulic power:4kw

3)Cooling system:fan cooling

5.Product table

1)Length:3m

2)Manual or automatic