ROOFING SHEET MAKING MACHINES - ZTRFM

Zhongtuo roofing sheet rolling forming machine

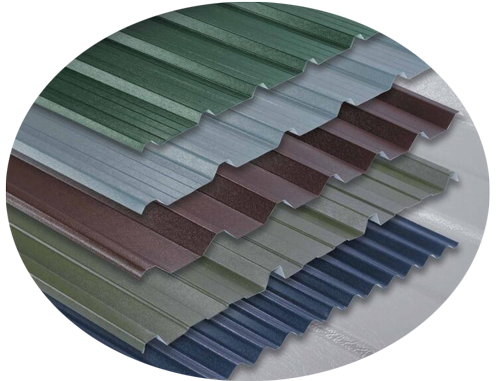

The finished products, color steel roofing sheets are suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decorations of large-span steel structure houses. It has light weight, high strength, rich color, convenient and quick construction, earthquake resistance, fire protection, rain protection, and longevity. Long, maintenance-free and other characteristics have been widely promoted and applied.

Double layer roofing machine

Round wave roofing machine

We have Roofing Sheet Making Machine.Metal roof sheets are an affordable option, able to withstand high temperatures for this purpose, ZTRFM roofing former offer to you Roofing Sheet Making Machine and Roof Panel Roll Forming Machine. It is the best reliable and affordable roofing system in the marketplace in a range of designs and styles.

Types of metal roofing panels :

Therefore, the ZTRFM group customizes various types roofing sheets and wall panels to you.you can see the following videos and know all of the roof tile panel and wall tile panel including:

- Popular design of R panel profile

- Max ribs panel profile

- TUFF-RIB PANEL profile

- Box Rib PANEL profile.

- AG metal PANEL profile.

- Corrugated PANEL profile

- STANDING SEAM METAL ROOFS profile

- Batten style panel profile

- GLAZED TILE profile

- Q tile machines and others.

Machine elements and each part detail introduction:

Actually most of roofing tile rolling forming machines is composed by the following elements:

Decoiler: we have both Manual type or hydraulic types of 5 ton, 7 ton 10ton or others.

Main rolling forming machine: the roller station and detail elements will be designed according to customer requirements and drawing profiles;

Receiving table, we have manual one and the fully aromatic stacker.

How to design proper metal roofing sheets machines?

For all metal roofing sheet machines we customize according to customer requirements. First we need the customer drawing profile and then we can give the proper design plan.

Step 1: get profile:

Get the drawing profile and then give customer proper feedback. Take the following drawing profile for example:

By the drawing profile can just that this drawing profiles is from north American and then we need to confirm with the customer input coil width and the material hardness. Different material and then the machine design will be different. Then we will give accurate drawing profile input coil width and then confirm with clients. Meanwhile recommend other popular designs in American for customers to choose.

Step 2: Design Machine according to customer requirements:

For example, if the customer have speed requirements, we have options high speed gearbox type metal roofing sheet machine. If the customer have durability requirements, we have molding frame strong version metal roofing sheet machine to recommend.

Step 3: Confirm order and arrange the production:

When finalize the order, we will stamp and sign the contract and quotation and then send to customer. Once we get the deposit from clients then arrange the production. Bur before we arrange the production, we will give the 3D or CAD file of machine layout and design then confirm with clients, like machine color, electricity and others.

Step 4 Testing and arrange the delivery of the metal roofing sheet machine.

Different with other factory, ZTRFM metal roofing sheet machine testing we use the coil not the single sheet. Normally speaking, by single sheet testing we can not find the big problem when rolling, like the measure length is not accurate, the sheet will go swing or others. In a word, we test the machines seriously like the customer is here. Meanwhile we have 12 webcams in our factory, you can check the machine testing by webcam at any time.

For more roofing sheet designs ZTRFM has more options for your reference:

- Stone coated metal roofing tile machines.

- Standing seam metal roofing sheet machines.

- Wall panel tiles rolling machines like snip-lock profiles.

- Roofing panel with felt rolling machines.

- Hot filming rolling forming machines.

Here are some popular drawing profiles for your reference,

please check flipbook to choose the proper drawing and then we can make the accurate quotation.

Roofing sheet with felt of PE form or anti-condensation material.

Here are more material for your reference: