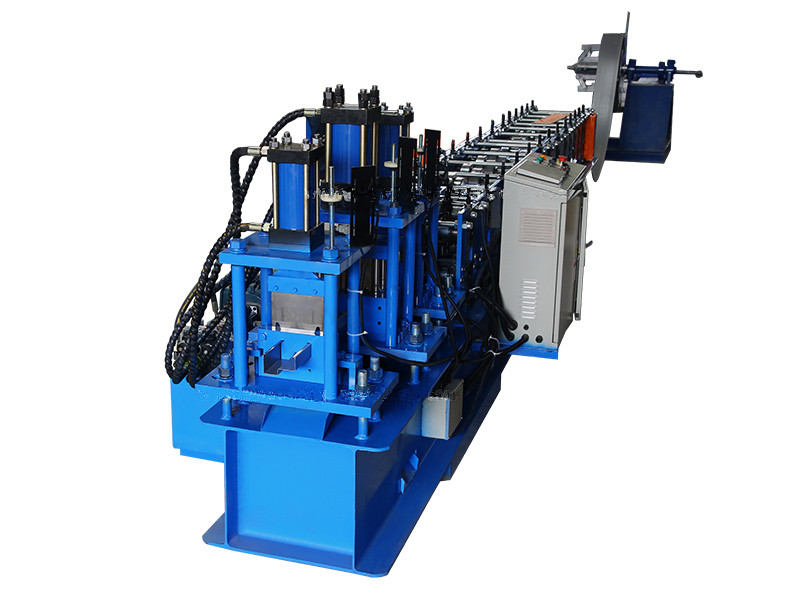

DOOR FRAME ROLL FORMING MACHINE - ZTRFM

Zhongtuo steel door frame roll forming machine

Door frame fully automatically machine

STEEL DOOR FRAME ROLL FORMING MACHINE

A Steel Door Frame Roll Forming Machine is for produce door frames as desired sizes. with multifunctional punch holes and notches for folding into frame.

Steel Door Frame Roll Forming Machine

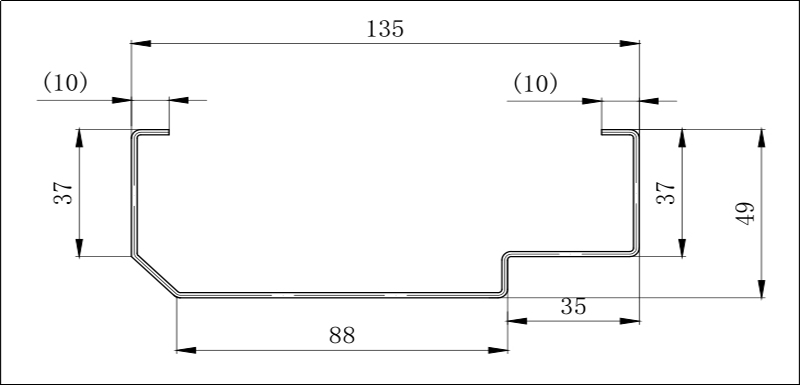

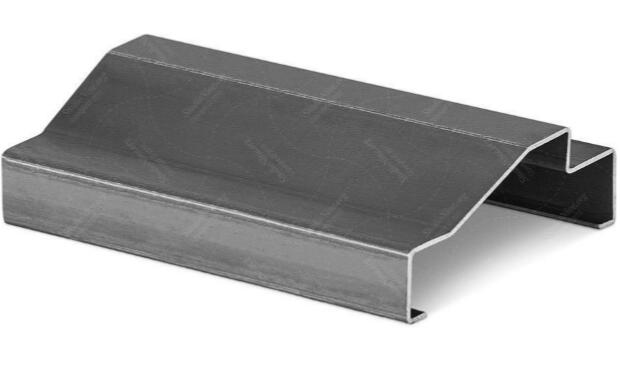

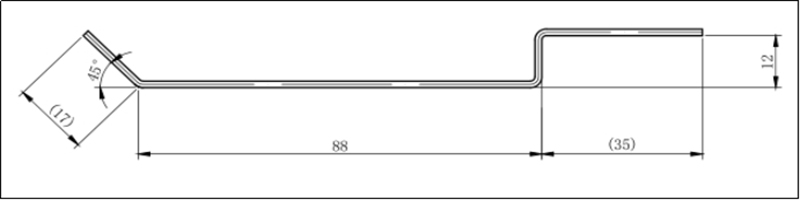

Steel Door Frame

The Steel Door Frame are light weight, sturdy, and manufactured from Galvanized steel with the thickness from 0.9-2.0mm.

The Steel door frames can be used extensively and are often preferred to timber due to their cost efficiency as they have installation advantages over timber door frames. Metal door frames can be easily fitted during construction or retrofitted. Their overall resilience and surface finish make them a popular and often more viable option to timber.

There are 2 main kinds of steel door frames:

Single Rebate Door Frame, The Doors only can be assembled in one side of the frame

Double Rebate Door Frame, The Doors can be assembled both side of the door frame

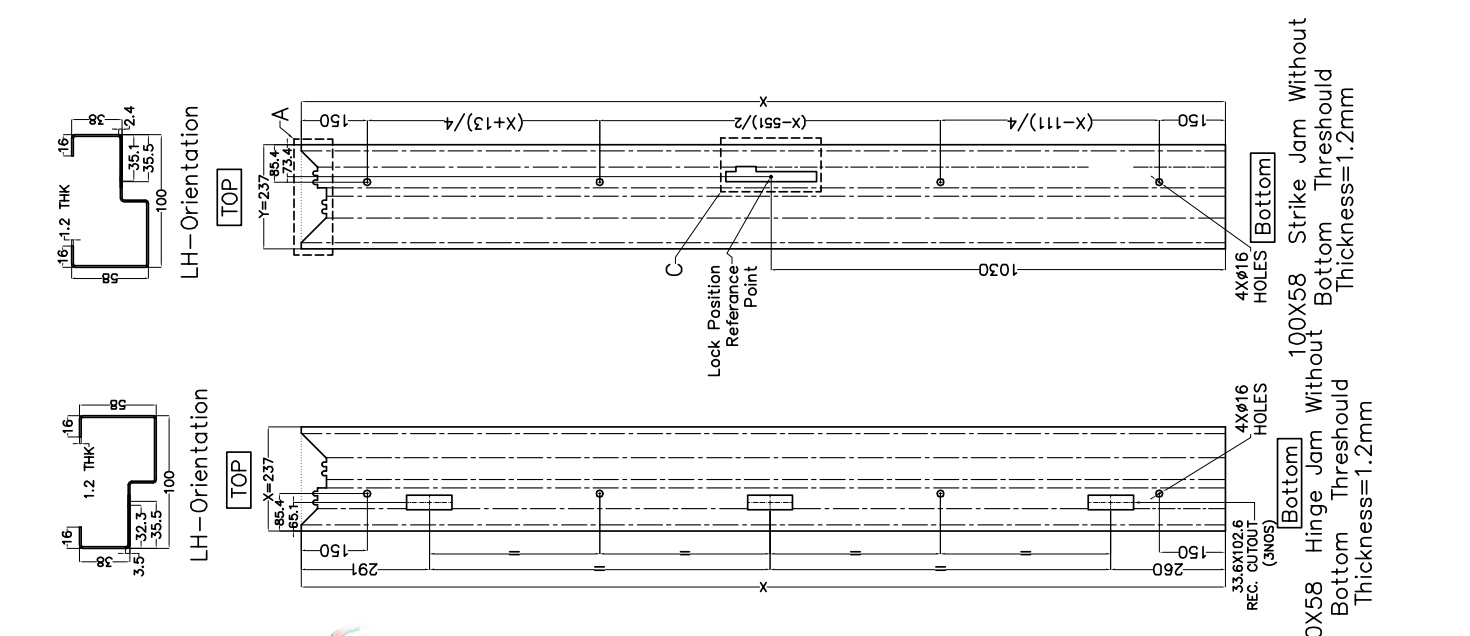

The Corners of Steel Door Frame

- Butted knocked down joint

- Welded Joint

- Mitered Joint

- Spot Welded joint

- Mitered welded

- Latest design, self joint. which is widely used in steel door industry. Believe Industry Company a whole automatic roll forming machine to produce such door frame

Steel Door Frame Roll Forming Machine Components and Specifications

3 Ton Electric Uncoiler

- Structure And Function: steel plate and beam welded structure, used for

supporting and uncoiling the steel strips. - Type: double head decoiler

- Decoiler Mandrel Expansion And Tension: manual adjust

- Expansion Range: 450-540mm

- Decoiling: electric decoiling

- Motor Power: 3 kw

- Maximum Capacity: 2000kg on each side

- Coil I.D: 508mm; Max Coil O.D: 1350mm

Levelling Machine

- Pneumatic adjust the gap between rollers

- Type: 2-roll pinch feeding, 9-roll leveling

- Diameter Of Leveling Roll: 80mm

- Material Of Leveling Roll: 40Cr, high frequency quenching

- Motor Power For Leveling: 3kw gear motor

- Main electric parts are all of famous brand

- Adopt Gear as transmission

- Limit Switch to ensure the speed of the leveling will be synchronous with the uncoiler

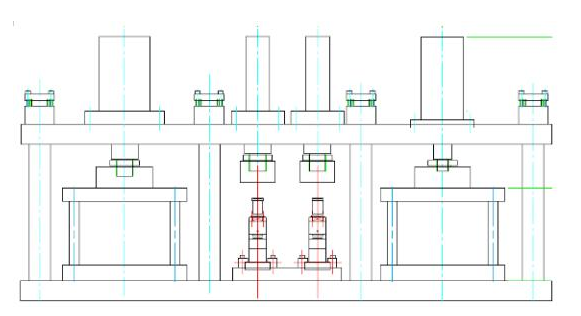

Punch Notches and Holes

- The punch device is used to punch notches for easy mitered folding( self joint), and punch holes for support, hinges and also locks.

- Servo motor power: 1.9kw

- Punching Device Structure: 4-guide pillar type

- Punching Mould: 1 set; Material: SDK11, HRC58-62

- Hydraulic Power: 11kw; Hydraulic Pressure: 20Mpa

- Electromagnetic valve: Beijing HUADE

Roll Forming Machine

- Machine Structure: Adopt H beam steel welded frame as the machine

- base, guide pole type roller stands screwed on the machine base

- Rollers Station: 22 forming steps

- Material Thickness:8-2.0

- Shaft Material: 40Cr HB220-260; Diameter: 75mm

- Roller Material: 45# steel, fine machining; roller surface chrome plated thickness more than 0.05mm

- Main Motor Power:11kw

- Forming Speed: 15- 20 m/min

- Drive: Chain and gear

- Speed Control: by Frequency Inverter