ROLLING SHUTTER MACHINE - ZTRFM

Zhongtuo rolling shutter forming machine

Perforated Roller Shutter door machine

Rolling shutter door machine

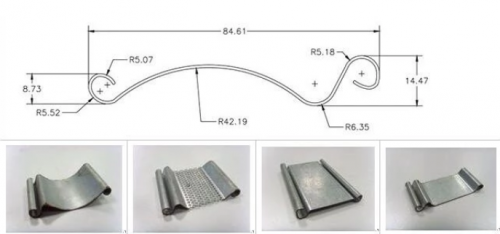

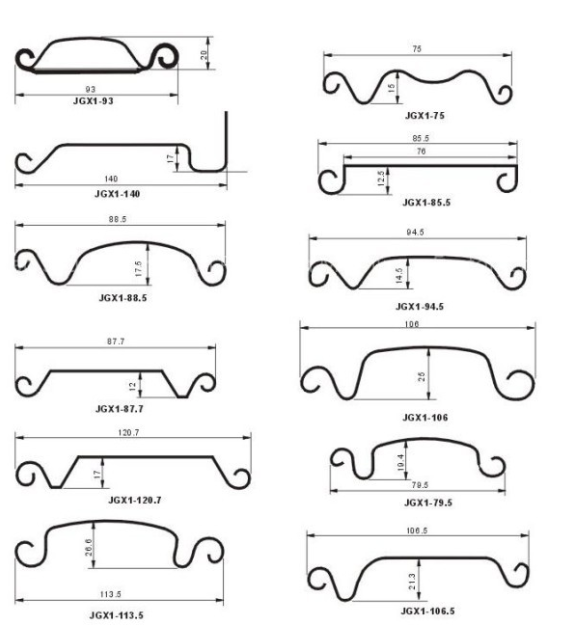

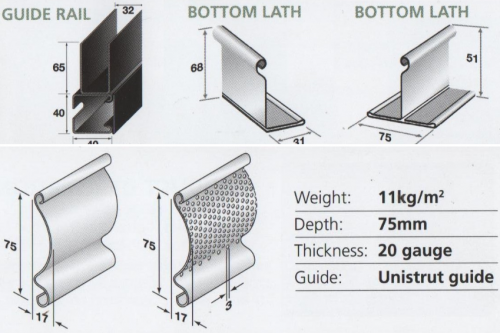

Here we share one article about the rolling shutter slat machine-single rolling shutter machine. As to the single roller shutter slat means the slats roll formed from galvanized steel or colour steel without PU insulation. The raw materials are typically 0.6-1.2mm GI steel or PPGI steel. There are so many different sizes of single slats that it’s not possible to list all roll formers. Generally, one regular single rolling shutter slat roll forming machine can make only one slats, with punching holes optional.

In whatever corner on the earth, developed countries, developing counties or undeveloped countries, rolling shutter doors are everywhere. However, not everybody uses the same roller shutter doors. For example, in developed countries, people prefer PU insulated rolling shutter door for Shop, Garage, Warehouse and even office buildings etc. But in other areas, we may see rolling shutter doors joint with single steel slats or just panels. Overall, any country in the world may use different rolling shutters, buy they all use rolling shutters.

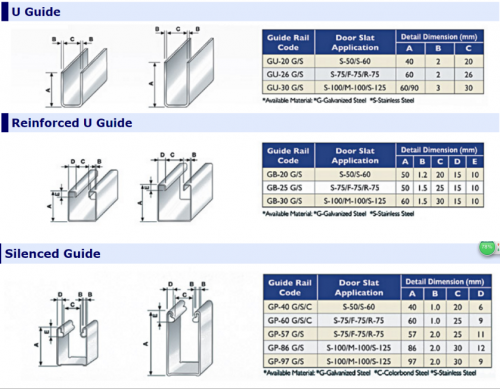

There are more types, we can not list all of them here. But for rolling shutter door related profiles, Zhongtuo machinery can handle most of type and make machines for you. For different profile, different requirements, for the machine design we also have different design like high speed rolling shutter door machine, slow speed rolling shutter door machine, gearbox type rolling shutter door machine, pillar type rolling shutter door machine and others.

The roller shutter door machine how to improve the production efficiency.

Firstly,the hydraulic station of roller shutter door machine has an energy accumulator.It can reserve energy and reduce the cutting gap of the post cutter,thereby improving the cutting speed and the production efficiency.

Then,the hydraulic station of roller shutter door machine has two motors. One is for cutting system,providing the power for the post cutter,thus improving the efficiency. Another is for punching system,enhancing the speed of punching .

Rolling shutter door machine two profile by one machine

Rolling shutter door machine two profile by one machine is designed to make two profiles by one machine. Zhongtuo rolling shutter door machines have the following types: Perforated Roller Shutter Roll Forming Machine, window and shutter rolling machine, Shutter Patti Machine, Australian Rolling shutters Machine, Aluminum window sill roll forming machine and other types. No matter which types, we can try to design two profiles by one machine, if the production rate you require is not high.

More parameters of the machine for your reference:

| Packing list for shutter door roll forming machine | ||||

| Part 1 | 1.5T decoiler | set | 2 | Manual |

| Part 2 | Roll forming system | set | 1 | Gear Box transmission |

| Part 3 | PLC control station | set | 1 | |

| Part 4 | Hydraulic system | set | 1 | YUKEN STANDARD |

| Part 5 | Product collect table | set | 1 | Pneumatic /3m length |

| Rolling shaft | Shaft material: 45# steel with quenched treatment, precision machined | |||

| Shaft diameter: 50 mm | ||||

| Roller | Roller material: Cr12 Mov with quenched treatment | |||

| Shaft diameter | 60MM | |||

| Machine structure | Steel plate welded structure, arch frame thickness 35 mm | |||

| Size adjustment | Adjust the spacers manually | |||

| Rolling station | 14 stations | |||

| Forming speed | 0-30 m/min | |||

| Machine frame | Vertical arch frame structure | |||

| Machine body | steel plate welded with grinding | |||

| Bearing | Chinese famous brand Harbin | |||

| Work power | 5.5 kw | |||

| Transmission | By chain | |||

More details of Zhongtuo rolling shutter door machine two profiles in One

- All the rollers we use the GCR12 material, hardness is enough for long time to use. Meanwhile carefully processing to make sure the surface of the rollers are smoothly.

- It allows to make many types embossing pattern, simple by adjusting the embossing rollers.

- With the flying tracking cutting saw to make sure the speed can reach 35 meter per minute.

- High quality hydraulic seals and valves to make sure shearing powerful and long time to use.

Check the profiles made by Zhongtuo rolling shutter door machine

- The rollers can protect the surface of the coil well. We can make sure the surface smoothly.

- Good and easy for installation. The two pieces parts could be smoothly connected, and we can make sure you use it well.

- Either for the embossing or without, those profiles could be made.