DOUBLE LAYER ROOFING SHEET MACHINE - ZTRFM

Zhongtuo double layer roofing sheet machine

Double layer roofing sheet machine

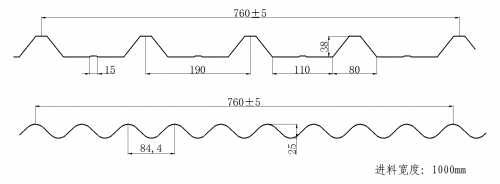

Double layer roofing tile machine profile drawings:

Our machine is customized, we will design and produce the machine as your personal requirements. Here below the profile drawings just for your reference only. This profile is the profile for our south africa customer. Different country have different profiles, if you want this machine please just give me your profile.

Double layer roll forming machine

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Length of the main part: About 8500 1650 1500 mm (L*W*H)

Weight of main part: 6.5 tons

Voltage : 380 V 50 HZ 3 PHASE(As customer’s need)

Roller fixer : Middle plate

Frame : 350 H steel welded

Drive mode: Chain

Material of rollers: 45# steel, surface hard chromium plating.

Material of shafts: 45# steel

Diameter of shafts: φ 80 mm

Number of rollers : 13 rollers(Up layer)15 rollers(Down layer)

Main power: 5.5 kw

Double layer roll forming machine Shearing Mechanism

Feature : Ensure stability, precision and cutting speed

It is used to make the step , the glazed tile’s final formed.

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Function : Automatic cutting controlled by PLC

Material of blades : Cr 12 quenched

Power supply : Hydraulic power

Components: It contains one set of blade, one hydraulic tank and one cutter machine.

Double layer roll forming machine Hydraulic Station

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Hydraulic motor Power: 4 kw

Hydraulic oil: 46# hydraulic oil

Volume: 30 L

Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes. and two sets of electromagnetism valves.

Double layer roll forming machine Electric Control System

1. Adopted PLC , transducer, touch panel to ensure high speed with stability, precision and lifetime.

2. Voltage: 380V 50 HZ 3 PHASE (As customer’s need)

3. Language: English and Chinese

4. Automatic length measurement

5. Automatic quantity measurement

6. Length Tolerance: 3 m±1.5 mm

7. Length inaccuracy can be amended easily.

8. Unit of length: millimeter (switched on the control panel)

9. Computer operating panel: touching screen and button together.