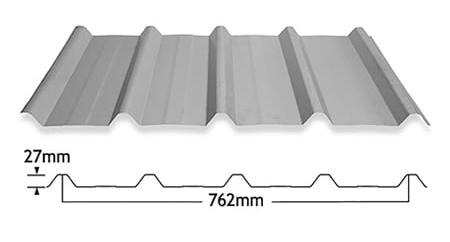

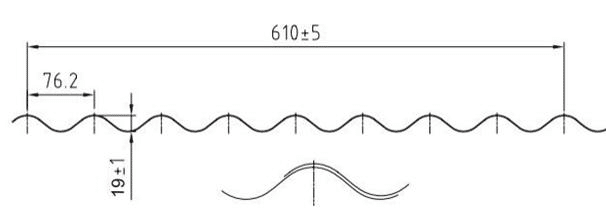

Laser welding shutter shaft tube rolling forming machine is designed to make the welded tube in batch fully automatically. Here I will show you the drawing profile for your reference:

For the shutter shaft tubes, there are very Specific Quality Requirements for Tube Rollers. A Tube Roller must be Straight, very Straight. Shade meet that straightness criteria for both the locked seam and the tube length itself. Packaging requirements are provided to keep each “Tubing Roller” safe from bending through normal shipping practices and then some. Special cartons and skids are designed to provide this for our Tubing Rollers. Based on the knowledge of knowing those, we design the Laser welding shutter shaft tube rolling forming machine, if the production rate is higher, you can also use the HF system to do the welding. Normally speaking, the laser welding speed is around 7 to 13 meter per minute but the HF welding can make the speed to 70 to 120 meter per minute. Welding system is adjustable, but here I will share the laser welding here.

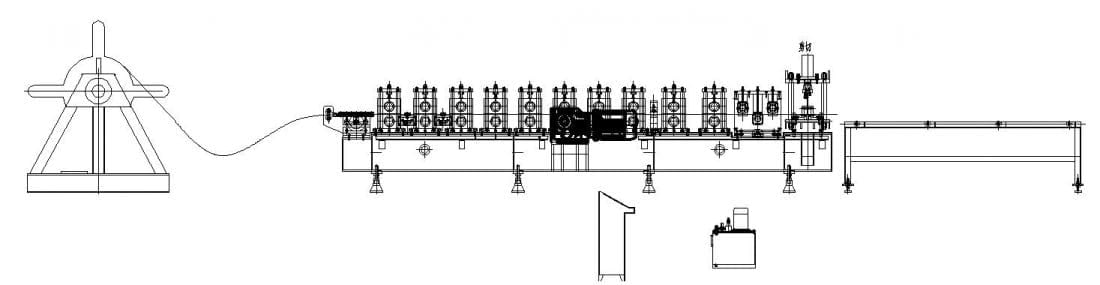

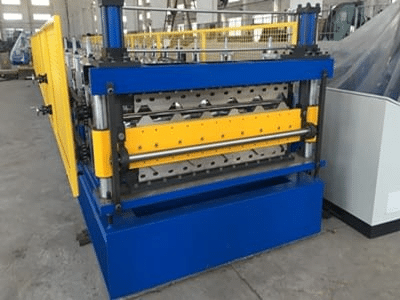

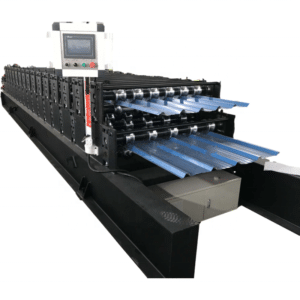

Main rolling forming machine:

Guidance holder, 1 sets.

Horizontal stands, 7 sets. the material of horizontal shafts is 40Cr, and the shaft is treat with tempering, high frequency quench, accurate grinding, rust prevention, the material of stands is are

- Vertical stands, 7 sets, the material of vertical shafts is 40Cr, and the shaft is treat with tempering, high frequency quench, accurate grinding, rust prevention, the material of stands is are HT200.

- Horizontal shaft O.D. is Ф50mm, vertical shaft D. is Ф30mm.

- Machine bed, 1 set.

- Universal drive shaft connecting system, 1 sets.

- Gear Box: ZhuJiang Brand with 1:30 ratio, 3 sets single thread type worm, and 3 sets of double thread type worm.

MCB: Schneider.

- Vertical shaft clamp roll, 5 pcs.

Gear box transmission

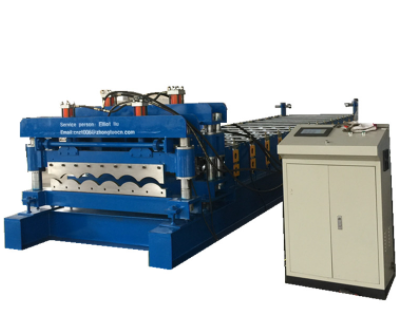

Laser Welding system:

Vertical stands, 2 sets, the material of vertical shafts is 40Cr, and the shaft is treat with tempering, high frequency quench, accurate grinding, rust prevention, the material of stands is are HT200.

Vertical shaft O.D. is Ф30mm.

Welding stand: three direction adjustment.

Laser welding features:

Suitable for welding of circular welds of stainless steel, carbon steel and other work pieces;

In mass production, the welding quality is stable and the welding is beautiful;

The welding speed is steplessly adjustable, and the operation is simple and convenient

Model: LV-Z3000

Laser power: 3 000W

Welding head: automatic

Laser wavelength: 1080±5nm

Spot size: φ0.2-1.8mm

Welding depth: 2-5mm

Adjust-ability of output power (%): 10-100%

Here we check Laser welding shutter shaft tube rolling forming machine working video for your reference:

Also we also make other type shutter tube machine based on the following drawing profile, if you need, please contact us at any time.