Solar mounting structure strut channel rolling forming machine

Description: Solar mounting structure strut channel rolling forming machine is designed to make the solar mounting structure strut channel in batch fully automatic by rolling forming principle.

What is the Strut channel ( wiki)?

Strut channel, sometimes called channel strut, supports lightweight structural loads such as wiring, plumbing, or HVAC equipment in buildings. Strut channel, often referred to colloquially by one of several manufacturer trade names, is a standardized formed structural system used in the construction and electrical industries for light structural support, often for supporting wiring, plumbing, or mechanical components such as air conditioning or ventilation systems. Here are some usage pictures for your reference:

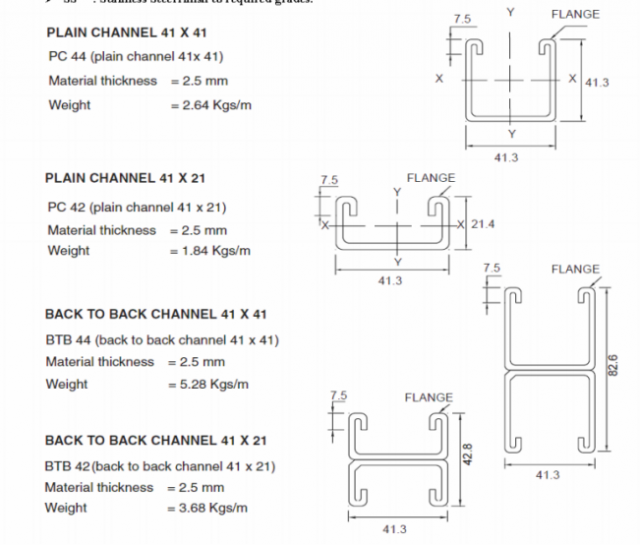

Drawing profiles-which type you prefer more?

STRUCT CAHNNELS MACHINE OPTIONS plain type without punching

Economic Design Option A

For the economic design, we use the middle plate as frame and using the GCR15 as the roller material, the machine design like the following pictures, the price is around 20000 USD for two sizes

Strong version Option B

For this design, we use the gearbox as transmission, and the molding frame as the machine based .And the flying tracking cutting system, the roller material is GCR12 mov, it is very very good one, the price is around 38000 USD, we can promise the straight edge of the corner

What we recommend and why?

What we recommend: that it is option B. As the machine, whole metal sizes frame is hard to change the roller and adjust them to make by one machine. You need to remove frame, chain and others and then you can change. And also for the material thickness beyond 2.5mm, we do suggest to use the gearbox as the transmission, as the chain transmission, you can not use more than 3 years. This profile is hard to bend as the size is small but the thickness is very thick. So it need more strength to make it.

STRUCT CAHNNELS MACHINE Pictures for your reference:

Working flow, normally it needs 30 meter long area, the distance between punching and main machine longer better?