Anti aging Insulated 4×8 aluminum composite roofing sheet

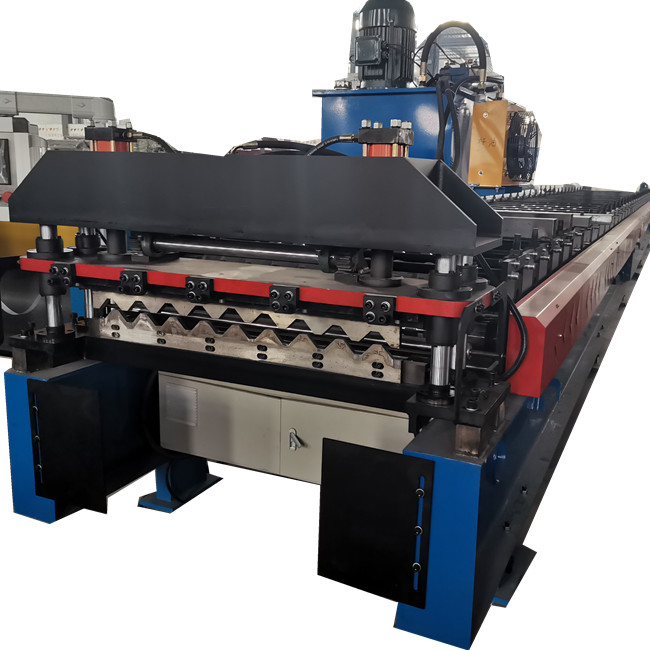

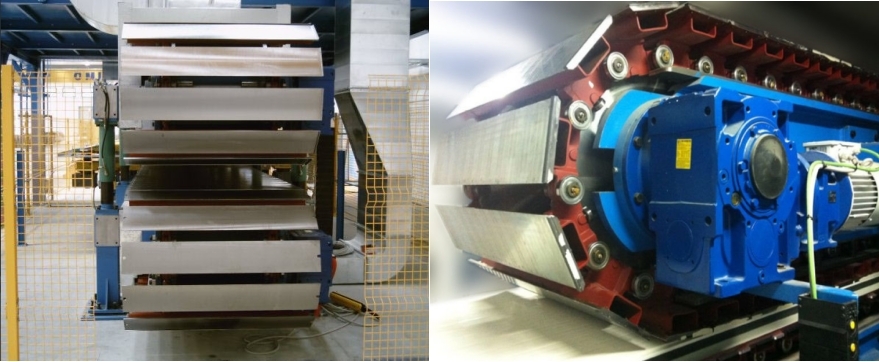

Recently, we have developed a new type of roof panel, which has a strong barrier effect. Next, I will give you a detailed introduction. Please click here for more information.

Product introduction:

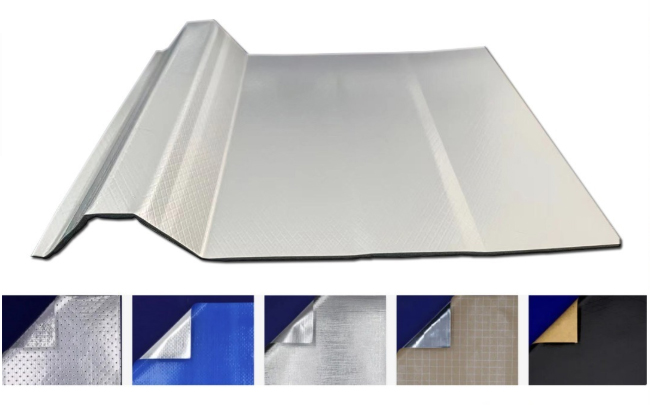

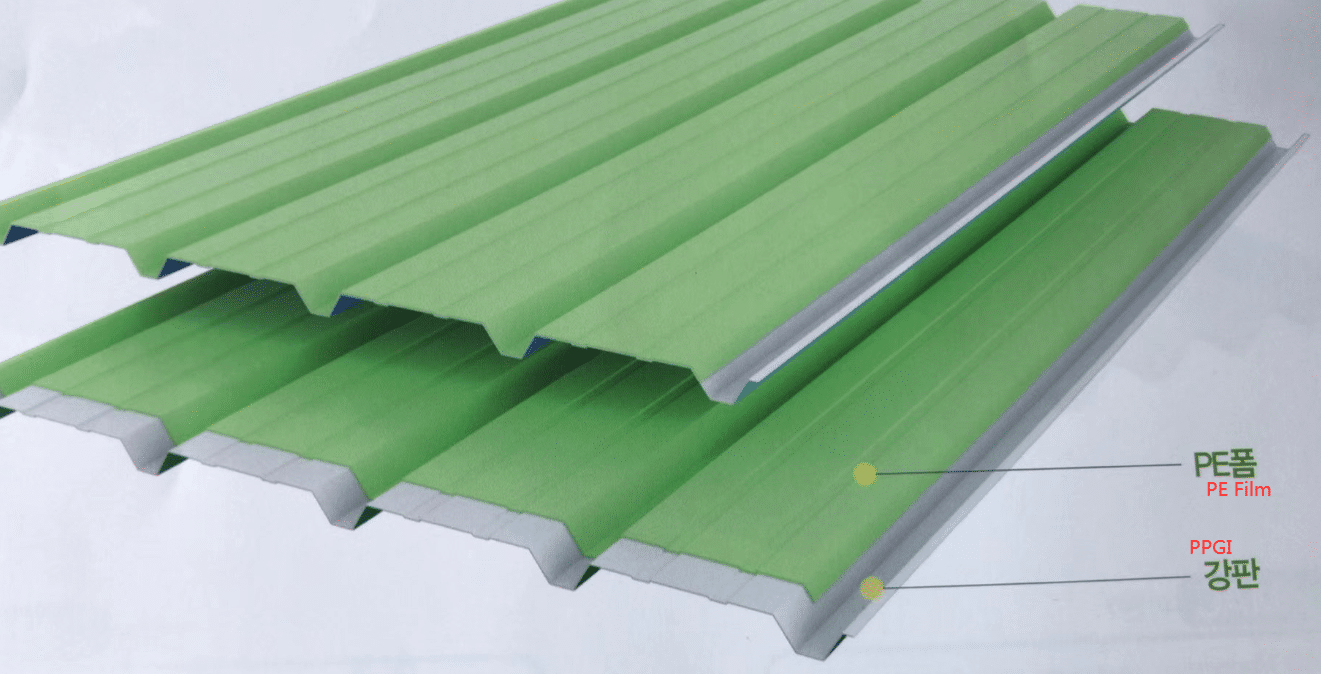

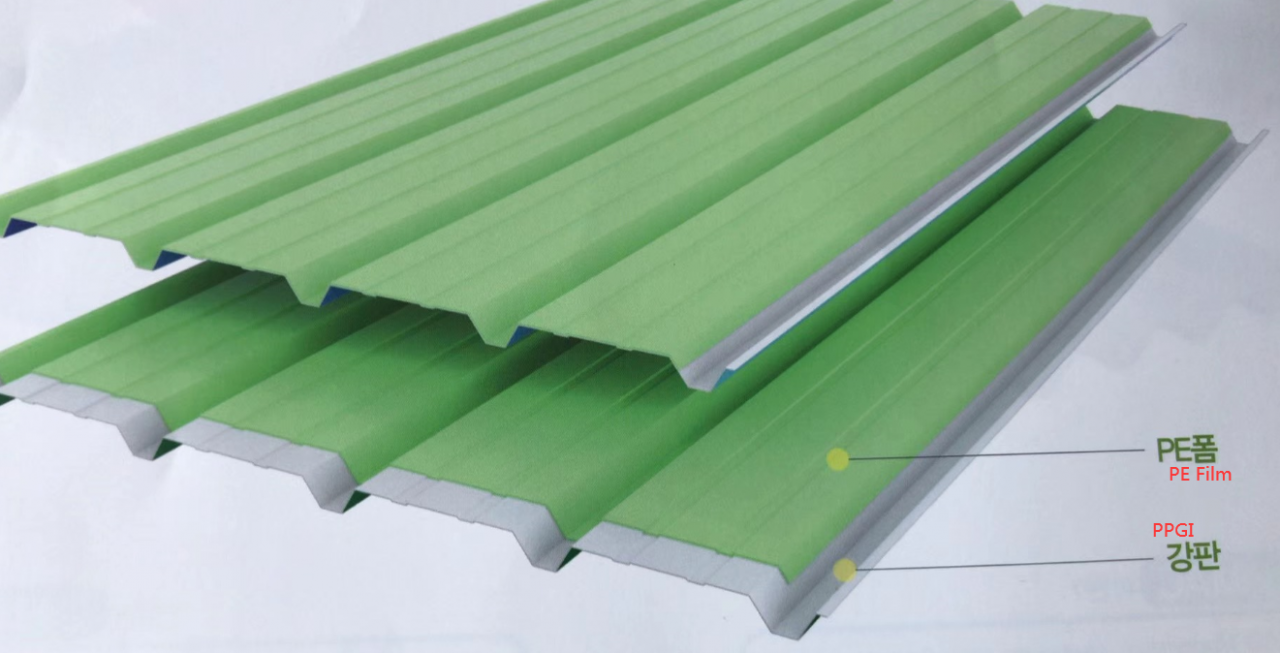

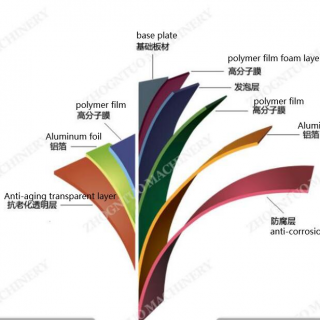

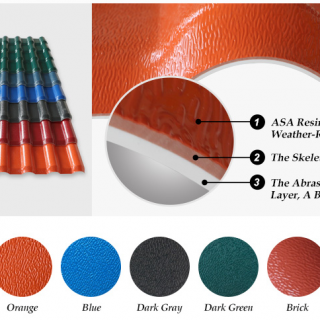

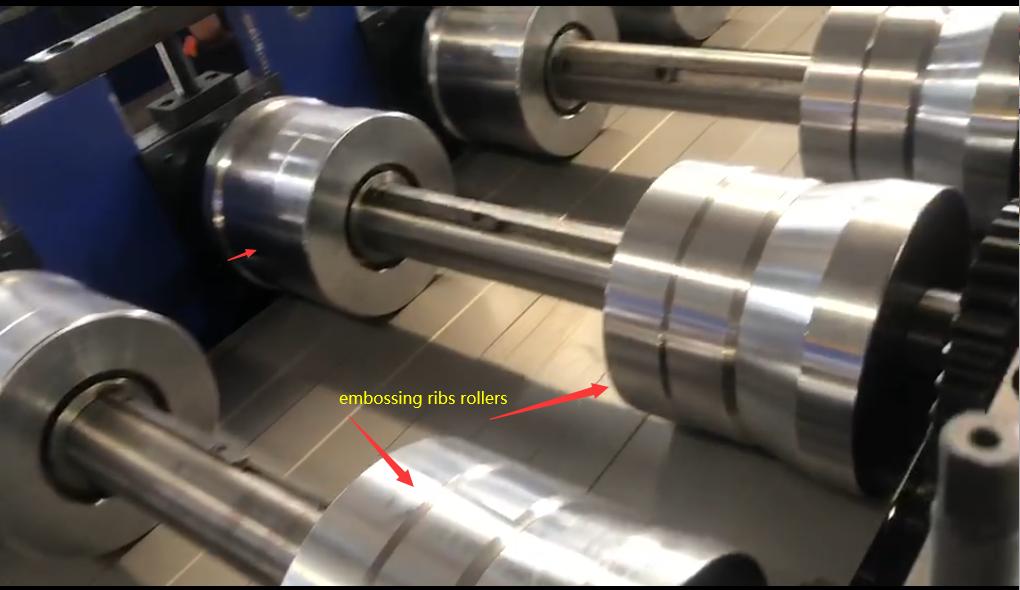

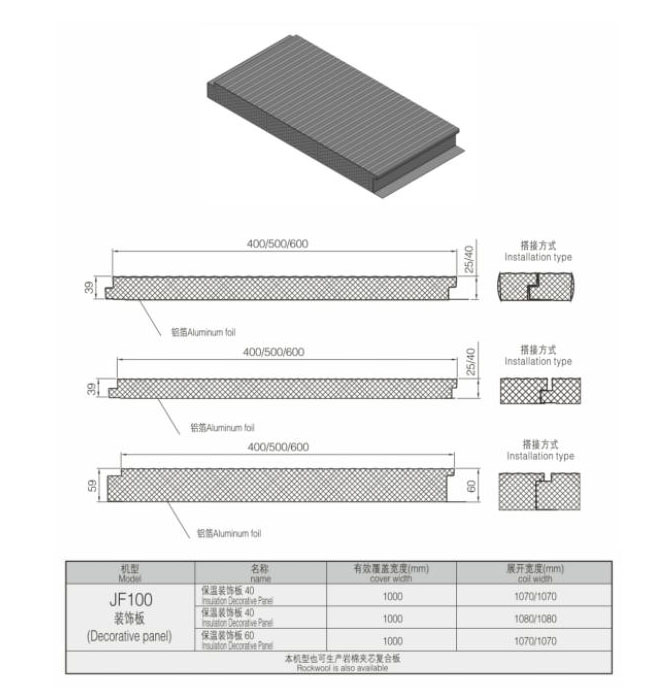

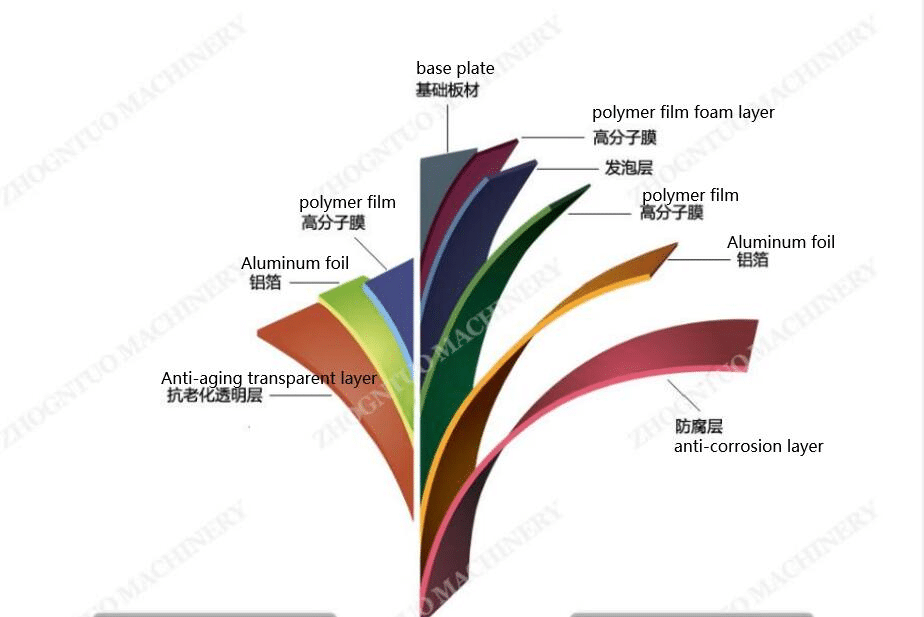

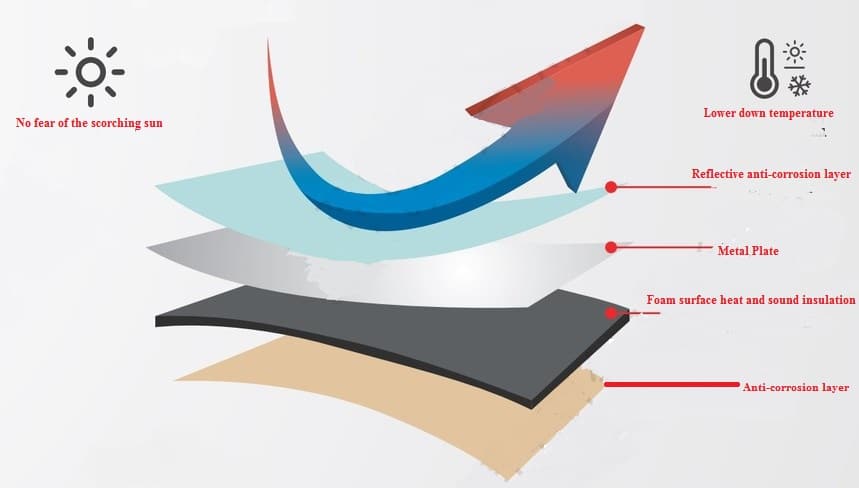

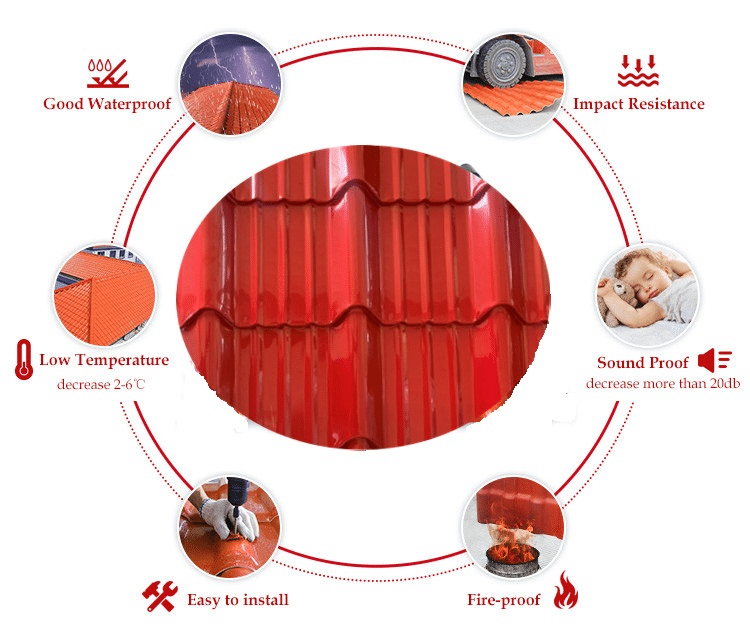

Compared with ordinary color steel plate, this roof sheet is multifunctional. Because it is composed of up to 8 layers of materials, and is processed through five high-temperature heat bonding processes and two high-strength anti-aging glue bonding processes. So it has a much better blocking effect, not only can it ensure that your house is warm in winter and cool in summer, but also put aside the noise outside, and give you a quieter life.

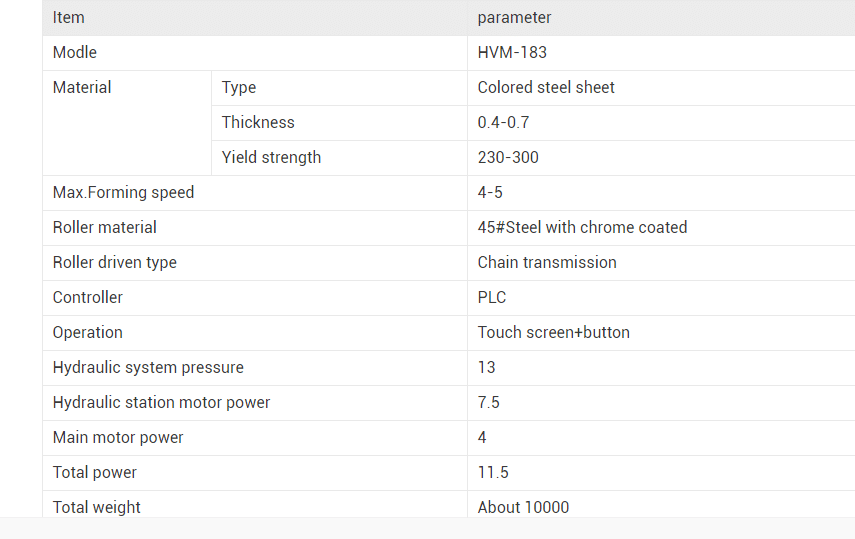

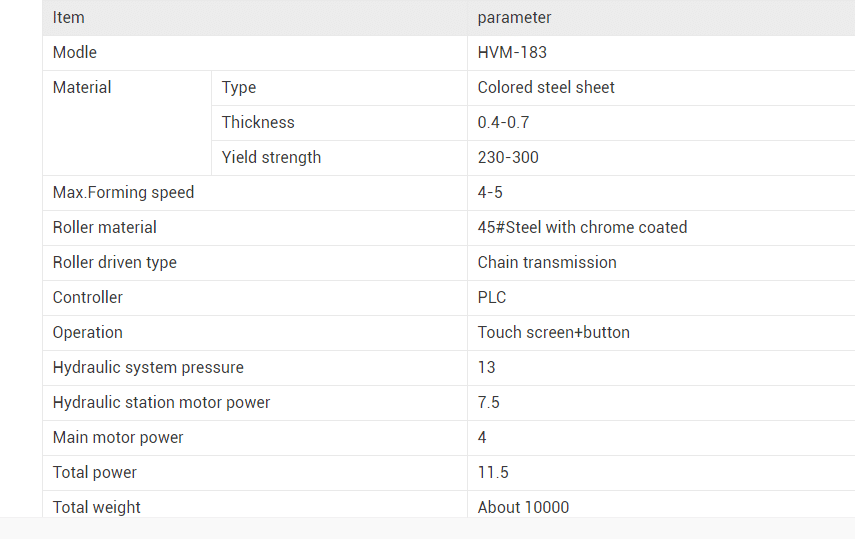

| Anti aging Insulated 4×8 aluminum composite roofing sheet | ||

| Model Choose | Basic model | 2 layers |

| Enhanced model | 5 layers | |

| Luxury model | 8 layers or customized | |

| Composition Material | Anti-aging film | Nature: PET Thickness : 36u |

| Polymer film | Thickness : 0.04 | |

| sheet-zinc layer of galvanized sheet/PPGI | thickness : 20g/m2 | |

| Foam layer | Material : XPE Thickness :2.5-3.0 |

|

| Aluminum foil layer | Mode : 8079#8111# thickness : 0.060.06 |

|

| Anti-corrosion | Material : XPE Thickness :2.5-3.0 |

|

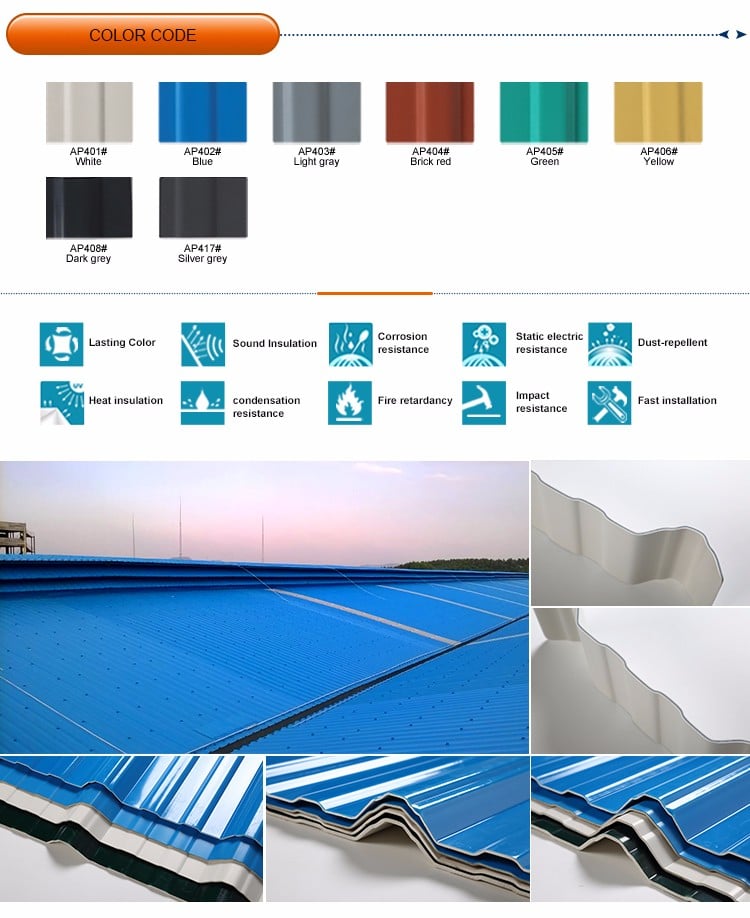

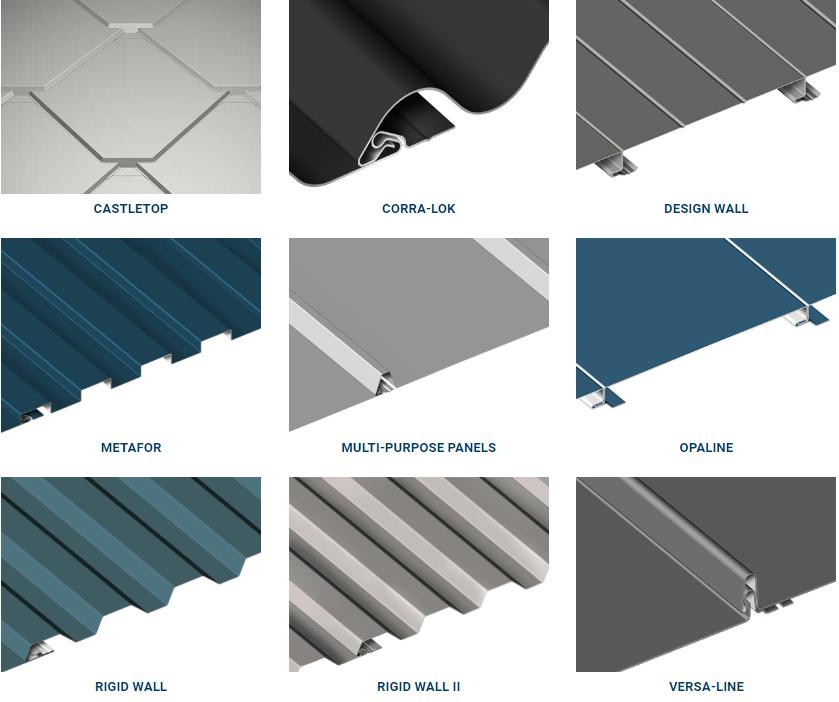

| color | customized | |

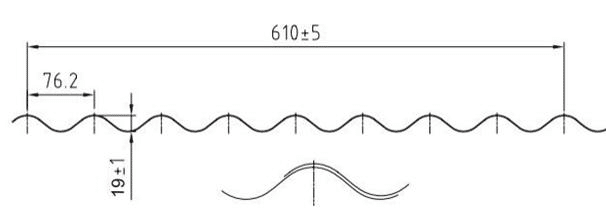

| shape | customized | |

In addition, thanks to its unique manufacturing process, its anti-aging effect is also better than other color steel plates, so choosing this type of roofing sheet is a wise choice for saving money .

CONTACT:

Do you have the following concerns before building a new house with color steel plates?

The color steel plate material is fragile, and the life of the house is short; or neither is it resistant to cold in winter, nor resistant to heat in summer; or the noise outside makes you unable to sleep in the middle of the night l, and even affects your daily life, etc. If you are facing these kinds of troubles, please contact us immediately.

TIPS:

Our productions can be customized to different shapes and colors accoring to your like.