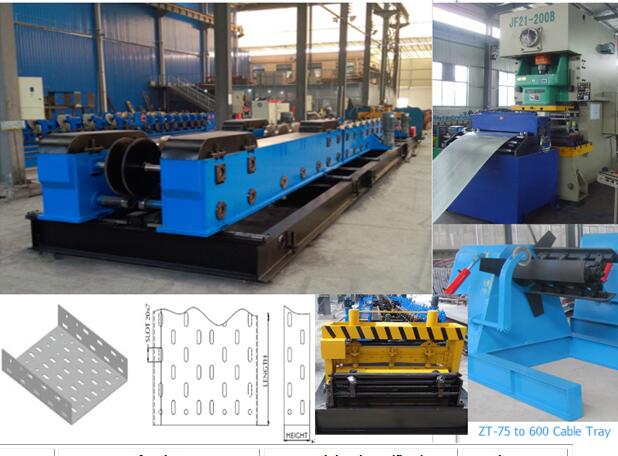

ZT-75 to 600 fully automatic cable tray rolling machine - ZTRFM

- Type:

-

Steel Frame & Purlin Machine, T-grids Metal Stud

- Applicable Industries:

-

Hotels, Garment Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Home Use, Food Shop, Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location:

-

India

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

Hot Product 2019

- Warranty of core components:

-

2 years

- Core Components:

-

PLC, Engine, Bearing, Motor, Pressure vessel, Gear, Pump

- Condition:

-

New

- Work Pressure:

-

16mpa

- Production Capacity:

-

20m/min

- Place of Origin:

-

Hebei, China

-

Brand Name:

-

zhongtuo

- Voltage:

-

380V 50Hz

- Power:

-

30kw

- Dimension(L*W*H):

-

12*1.5*135m

- Weight:

-

3000 kg

- Warranty:

-

2 years

- Key Selling Points:

-

High-accuracy

- Name:

-

cable tray making machine

- Product name:

-

cable tray

- Roller material:

-

45# Steel Chrome-faced

- Usage:

-

Construction Building Material

- Suitable material:

-

Q235 Galvanized Steel Coil

- Material Thickness:

-

1.5-2.0mm

- Control System:

-

PLC: Delta

- After sales service provided:

ZT-75 to 600 fully automatic cable tray rolling machine produced cable trays that are used in different kind of factories and buildings. We offering you to Cable Tray Machine that comprise of efficient Punching Press, Hydraulic Press, Electric Control panel and many other Equipment, which make it an ideal option for

many. The Cable Tray Roll Forming Machine can Manufacture a both superiority and quantity cable trays in less time.

Composition

What is the Application of cable tray machine?

Galvanized Steel cable tray machine is a kind of equipment for making cable tray by various material. In the electrical wiring of buildings, a cable tray system is used to support insulated electric cables used for power distribution and communication. Cable trays are used as an alternative to open wiring or electrical conduit systems, and are commonly used for cable management in commercial and industrial construction. They are especially useful in situations where changes to a wiring system are anticipated, since new cables can be installed by laying them in the tray, instead of pulling them through a pipe. For zhongtuo cable tray roll forming machine is a kind of machine for making cable tray by roll forming principle.

Zhongtuo cable tray machine is composed by the following elements:

de-coiler

Inner diameter of coil: 508mm;inner expansion range: 480-520 mm;

The maximal of Diameter: 1500mm; The Maximal of loading: ≤5T

Motor power: 5.5kw frequency change control

Press material type: pneumatic press material

Feeding speed: 0-15m/min, adjustable

Features of main cable tray rolling forming machine:.

Thickness:1.0—2.0 mm;

Forming speed:3—6 m/min

Lateral plate:27 mm steel plates

Body of machine:350H welded steel plate

Motor power:Main transmission: 4KW K series of spin chute gear motor 2

Sets, 5.5 KW K series of spin chute gear motor 2 sets.

Motor power of side-to-side adjustment:1.5 kw motor 1 set, 1.1 kw motor 1 set.

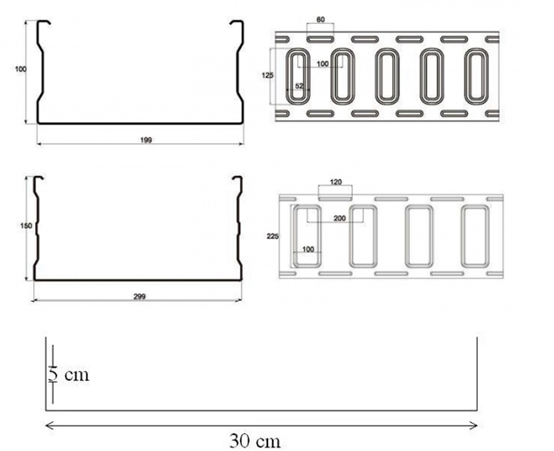

Adjusting range of side-to-side:100mm-600mm.

Adjusting range for height of lateral plate: 50-200mm.

at the same time, can produce cover board (with width of 100~600 mm)

(Width and depth are adjustable. Error on working length: ±1.5 mm.

Straightness error 2‰).

For this machine, if you want to know more videos, please cotact us

3 Ton Manual De-coiler

|

3 Ton Manual De-coiler

|

|

|

Type:

|

passive

|

|

Coil width:

|

max 400 mm

|

|

Loading capacity:

|

3 tons

|

|

Inner diameter:

|

450-550 mm

|

B: Feature of structure: after the quenching and tempering, chrome-plating processing, the rigidity, surface roughness of the roller etc. are all enhance greatly; It is composed by the clamping roller and the leveling roller, the clamping roller may the independent control, the leveler has one pair of horizontal guide roller and two pairs of vertical guider roller and easy to adjust by hand wheel. Between the leveler and the feeding device, there is optical

sensor, sends out the feedback signal to the control system, the control system sends out the instruction to the frequency

conversion motor to change speed, Achieves the uninterrupted level goal.

Model of punching press: JF21-120B

Forming variety: bridge frame

The diameter of the roller axis: 85mm

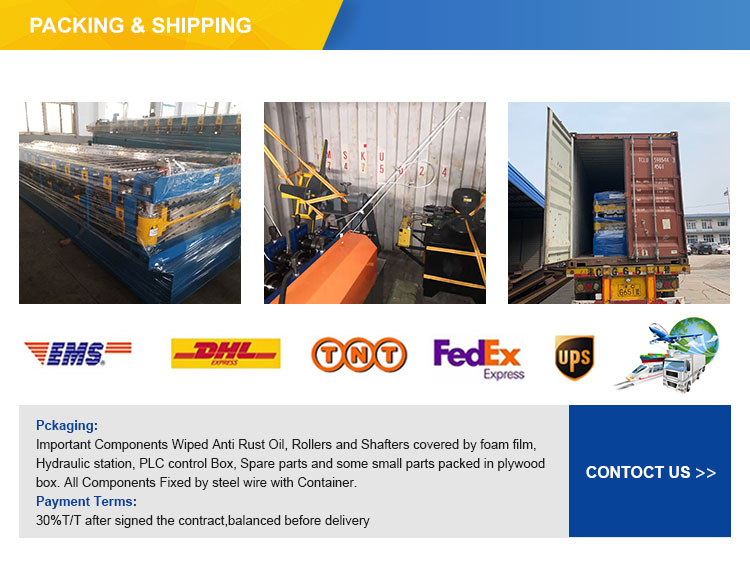

Packing & Delivery