ROOFING SHEET MACHINE FOR USA - ZTRFM

Zhongtuo Roofing sheet machine for USA

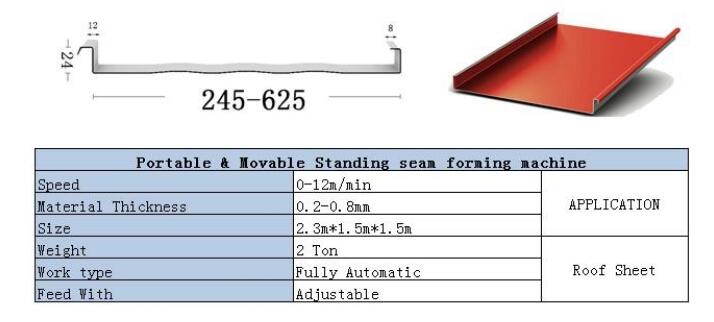

Portable & Movable Standing seam forming machine

This machine is a special machine designed by us. We have appliedfor a patent. It is not only lightweight, but also equipped with wheelsfor easy movement. This machine can be moved to the constructionsite for construction. The production process is controlled by the PLCcontrol system, which is a fully automated production.

Here are the USA popular roof panel machines for your reference:

Maxima Standing Seam Panel Machine

With an opportunity to choose from three distinct Maxima profiles: Maxima, Maxima 1.5 and Maxima ADV, McElroy’s Maxima family of products represents the industry’s broadest selection of vertical leg standing seam systems. In order to meet the varying needs of architects and contractors, each offers unique performance characteristics that enable users to match a Maxima panel to specific aesthetic and performance specifications. In some cases, Maxima panels can be produced on-site by McElroy factory technicians. Maxima 1.5″ & 2″ panels can also be curved for use with radius roof situations.

All Maxima panels are mechanically seamed.The rental fees for each type of equipment can be found on this site as well as additional information you may need to be aware of within the terms and conditions. Dl is the only approved supplierfor this type of equipment.

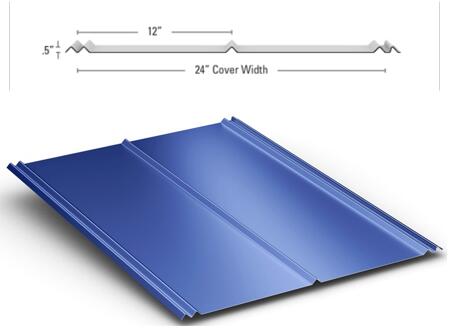

5V Metal Roofing Panel Machine

Homeowners across the country are discovering that 5v

metal roofing not only adds value to their home but providesbeauty as well. Zhongtuo 5V panels are 24″ wide and incorporatea classic design that adds beauty to any home. 5V is also commonlyinstalled as an interior liner or accent panel.

Zhongtuo 5v panel is available with fade and chalk resistantKynar 500/PVDF coatings, which provides assurance that aroof retains its like-new beauty year-after-year.

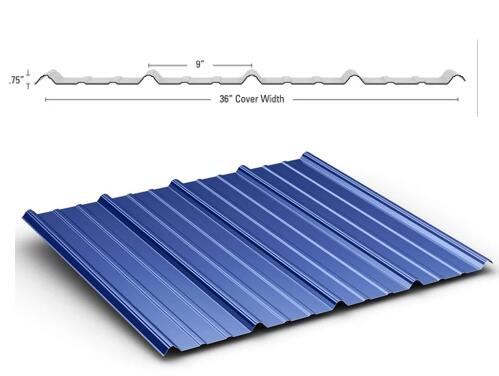

Max-Rib Panel Making Machine

Max-Rib is a low profile (3/4″)panel that is equally well suited for residential roofing and post frame applications.Varying applications, end uses, and expectations require different metal panel alternatives.Fortunately, ZhongtuopopularMax-Rib profile is available in five distinct options:Max-Rib Ultra,Max-Rib ll, Max-Rib 100, and Max-RibCommodity/Liner.The best choice for your individual project depends on factors such as performance,desiredlongevity, and budget.

Combining the long-life characteristics of a Galvalume steel substrate with the proven performanceof a high-quality Silicone Modified Polyester (SMP) coating,Max-Rib ll is an excellent multi-use metalpanel.

Combining a zinc-coated G100 Galvanized substrate with a high-quality Silicone Modified Polyestercoating,Max-Rib 100 is an ideal panel when a Galvanized substrate is required.

Max-Rib Commodity/Liner is a 10-year warrantied economical panel that is ideal for interiorapplications such as liner panel or basic shade and shelter applications.

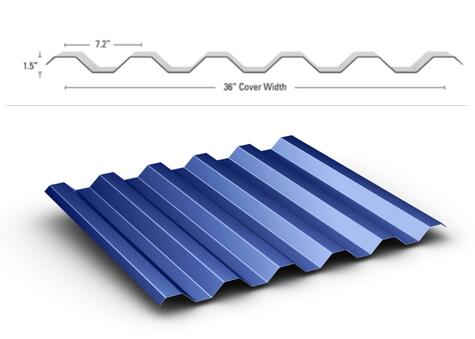

Mega-Rib Panel Making Machine

Mega-Rib is a 7.2 exposed fastener panel that provides optimum strength and spanning capabilities. Mega-Rib is a metal roof and wall panel that is equally well suited for industrial and commercial applications. Installed horizontally, Mega-Rib’s bold ribs provide a hard to beat architectural statement.

MESA Panel Making Machine

Many post frame and residential panels look identical from manufacturer to manufacturer.Mesa is a patent and copyright protected panel that can’t be copied and features a nearlyinvisible lap offering a distinctive look.

Mesa’s standard paint system is Kynar 500® (PVDF), the industry’s best coating for long-term protection against panel chalk and fade.

Multi-Cor and M-Cor Panel Making Machine

While quickly communicating their high-strength performance attributes, McElroy’s corrugated metal panels are reminiscent of yesteryear and simpler times. Consistent, rounded corrugations make Multi-Cor and M-Cor ideal panels to achieve nostalgic appeal whether installed as a wall, roof or interior accent panel.

For added aesthetic appeal, horizontal installations showcase corrugated design capabilities. Multi-Cor and M-Cor are similar in design, with M-Cor offering a more subtle rib height and configuration.

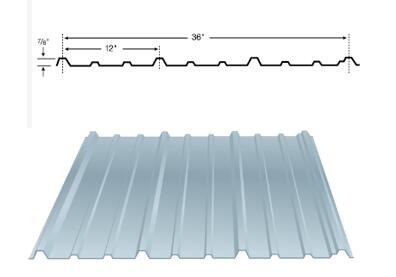

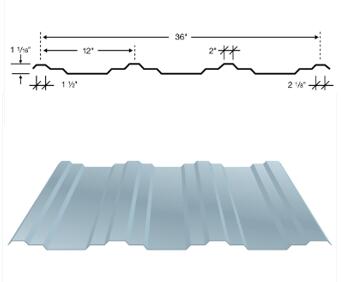

Multi-Rib Panel Making Machine

Multi-Rib is McElroy’s proprietary version of the industry’s standard R-Panel and is a multi-use roof and wall rib panel primarily used in pre-engineered metal building applications. An optional purlin bearing leg (PBR) rests on purlins and provides support for fastening the panel lap.

Multi-Rib is also commonly utilized for residential roofing, primarily in the Southwestern region. Featuring 1 1/4″ major ribs, 12 inches on center, Multi-Rib’s bold profile adds a distinct beauty to any home.

R-Panel Making Machine

R-Panel is a multi-use wall and roof panel used primarily in pre-engineered metal building applications. R-Panel is also a popular choice for residential metal roofing, especially in the Southwest. An optional purlin bearing leg (PBR) rests on purlins and provides support for fastening the panel lap.

Fade and Chalk resistant Kynar 500 (PVDF) coatings are a McElroy Metal standard for R-Panel and provide building owners with a long-term, high performing panel that retains its original color and beauty year after year.

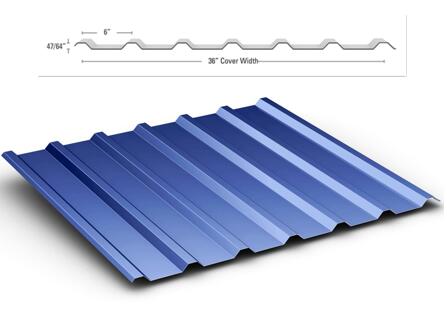

U-Panel Making Machine

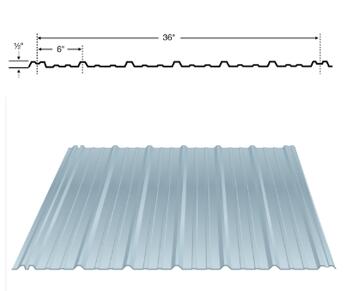

U-Panel is an exposed fastened wall and roof panel. With a ¾” (approximate) rib height and 6” on center rib spacing, U-panel offers a lower profile and softer appearance than R-Panel or Multi-Rib. U-Panel is widely utilized as a liner panel or partition wall.

⅞ WIDE RIB ROOFING SHEET MACHINE

This exposed fastener panel is the ideal choice for rural and agricultural customers.

The traditionally designed ⅞ Wide-Rib features uniform ribs, setting it apart from other panels in the industry. With this panel, cost-conscious customers don’t have to sacrifice the budget for the aesthetic they desire.

- Applications – Roof

- Coverage Width – 36″

- Rib Height – 7/8″

- Panel Attachment – Exposed Fastening System

- Gauge – 29 and 26

- Finish Type – Siliconized Polyester

- Related Industries: Agricultural, Post-Frame

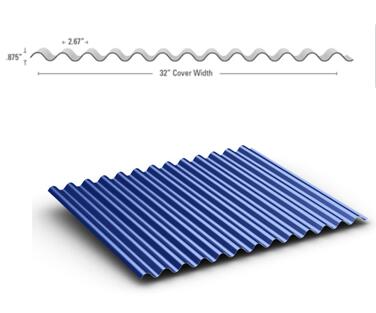

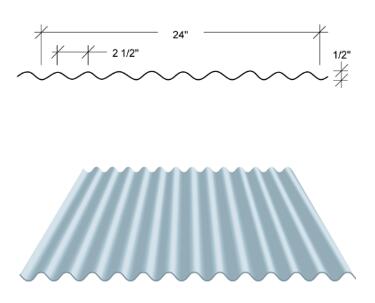

2 ½ CORRUGATED METAL PANELS MACHINE

The 2 ½ Corrugated exposed fastener panel offers a traditional visual appeal with a high rib profile that customers often seek.

Designed with bold curves, the 2 ½ Corrugated panel offers a classic aesthetic while providing durability your customers can depend on. These high-quality metal roof and wall panels maintain their strength and structural stability throughout the building lifetime.

- Applications – Roof and Wall

- Coverage Width – 24″

- Rib Height – 1/2″

- Rib Spacing – 2 1/2″ on center

- Panel Attachment – Exposed Fastening System

- Gauge – 29 (standard); 26 (optional)

- Texture – Smooth (standard)

- Coatings – Galvalume Plus

- Related Industries: Post-Frame

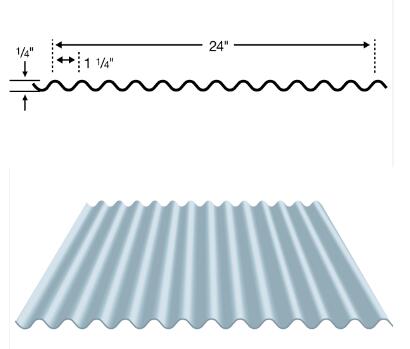

1 ¼ CORRUGATED METAL ROOFING PANELS MACHINE

The 1 ¼ Corrugated exposed fastener panel combines traditional style with innovative design popular among metal building professionals in various industries.

The 1 ¼ Corrugated panel features strong ridges, providing customers with the uncompromising strength and stability they need to get the job done. These versatile, durable panels are the ideal choice for seasoned builders because they offer exceptional quality at an economical price.

- Applications – Roof and Wall

- Coverage Width – 24″

- Rib Height – 1/4″

- Panel Attachment – Exposed Fastening System

- Gauge – 29, 26, 32 (Galvanized)

- Finish Type – Siliconized Polyester

- Coatings – Galvalume Plus

- Related Industries: Agricultural

AMERI-DRAIN ROOFING SHEET MACHINE

This popular exposed-fastener panel offers a traditional look suitable for all your customers’ building projects.

The traditionally designed Ameri-Drain® panel offers your customers durability they can depend on for their building projects. This cost-efficient panel will hold its value for decades to come, making it a valuable investment.

- Applications – Roof and Wall

- Coverage Width – 36″

- Rib Height – Major Ribs 1/2″

- Panel Attachment – Exposed Fastening System

- Gauge – 29 and 26

- Finish Type – Siliconized Polyester

- Coatings – Galvalume Plus®, Signature® 200

- Related Industries: Agricultural, Post-Frame

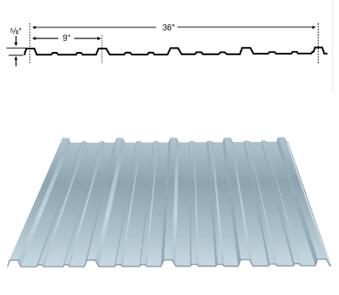

PERMA-CLAD ROOFING SHEET MACHINE

This exposed fastener panel is well-suited for many building projects in a variety of settings, making it the ideal solutions for a large number of customer needs.

Perma-Clad panels are designed with your customers’ unique needs in mind. The all-weather durability of these panels makes them the ideal choice for all climates and conditions.

- Application – Roof and Wall

- Coverage Width – 36″

- Rib Height – 5/8″

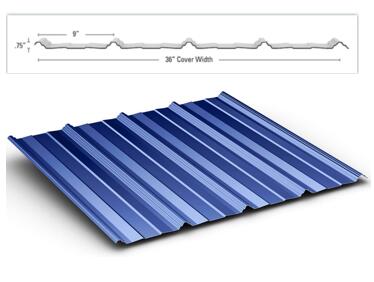

- Rib Spacing – 9″ on center

- Panel Attachment – Exposed Fastening System

- Gauge – 29 and 26 Texture – Smooth (standard)

- Finish Type – Siliconized Polyester

- Coatings – Galvalume Plus®, Signature® 200

- Related Industries: Agricultural, Post-Frame

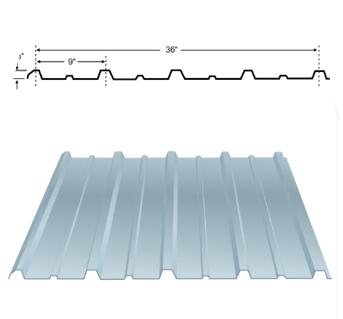

REGAL RIB ROOFING SHEET MACHINE

This panel provides consistent performance your customers can count on to get the job done no matter the industry or application.

The Regal Rib panel provides long-lasting structural stability cost-conscious customers look for. Unique amongst other panels in the industry, Regal Rib provides the strength and durability your customers can depend on.

- Application – Roof

- Coverage Width – 36″

- Rib Height – 5/8″

- Rib Spacing – 9″

- Panel Attachment – Exposed Fastening System

- Gauge – 29 and 26

- Finish Type – Siliconized Polyester

- Coatings – Galvalume Plus®, Signature® 200

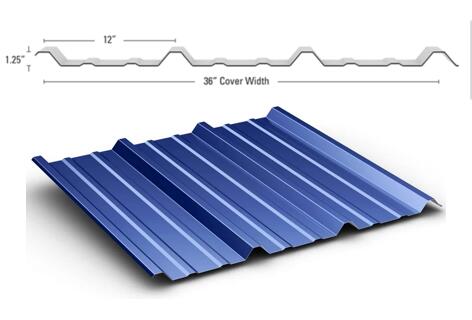

RETRO-R ROOFING SHEET MACHINE

The Retro-R panel is an economical option for your customers. It can be installed over any existing R-panel roof, so your customers easily extend the life of their roof at a reduced cost.

The Retro-R metal panel is an excellent choice for customers looking to prolong the life of a building without damaging the existing roof. A cost-efficient solution, the Retro-R panel is a high-quality, lightweight option that offers durability and strength.

- Application – Roof and Wall

- Coverage Width – 36″

- Rib Height – 1 1/16″

- Rib Spacing – 12″ on center

- Minimum Slope – 1/2:12

- Panel Attachment – Exposed Fastening System

- Gauge – 29 (standard); 26 (optional)

- Texture – Smooth (standard); Embossed (optional)

- Finish Type – Siliconized Polyester

- Coatings – Galvalume Plus®, Signature® 200

RUGGED RIB ROOFING SHEET MACHINE

This high-quality, exposed fastener panel is the superior choice for all your customers’ building projects, no matter what industry or building application.

Rugged Rib panels are strong and durable which adds value to your customers’ buildings. These cost-effective metal panels are guaranteed to perform at optimal levels year after year, making them the best choice for your customers.

- Application – Roof and Wall

- Coverage Width – 36″

- Rib Height – 9/16″

- Panel Attachment – Exposed Fastening System

- Gauge – 29 and 26

- Finish Type – Siliconized Polyester

- Related Industries: Agricultural, Post-Frame

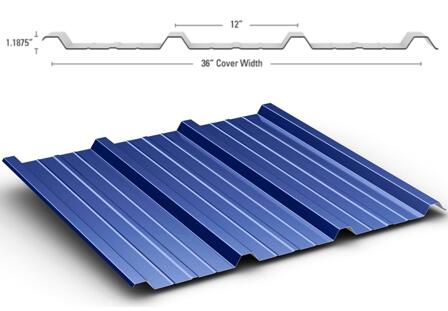

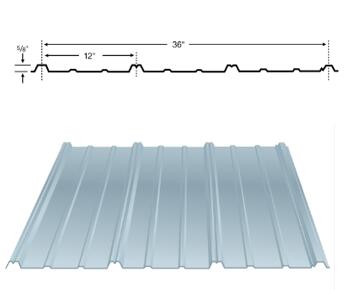

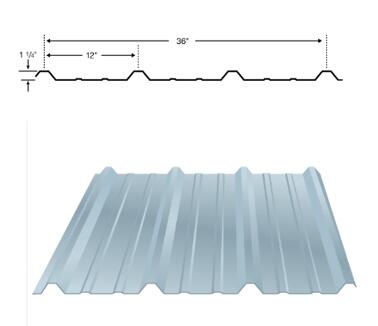

PBR ROOFING SHEET MACHINE

The versatility of this exposed fastener metal roof and wall panel makes PBR a classic choice for your customers’ building projects.

The PBR metal roof and wall panel is a high-quality, versatile option. They can be easily installed both horizontally and vertically, ensuring a functional design that meets the requirements of your customers’ building projects.

- Applications: Roof and Wall

- Coverage Width – 36″

- Rib Height – 1 1/4″

- Rib Spacing – 12″ on center

- Panel Attachment – Exposed Fastening System

- Gauge – 26 (standard); 29, 24, 22 (optional)

- Finish Type – Siliconized Polyester

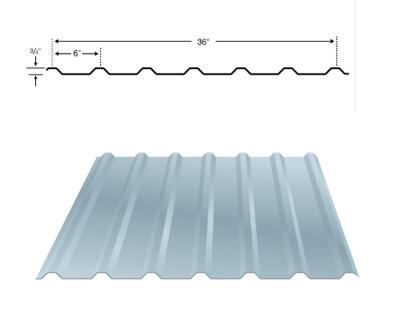

PBU METAL PANELS ROOFING SHEET MACHINE

Our most versatile profile, this exposed fastener panel can be installed vertically or horizontally.

The PBU panel can be installed horizontally or vertically, making it a versatile option for your customers’ roof & wall panel applications. This cost-efficient, high-quality metal panel provides your customers with durability they can trust to get the job done.

- Applications – Roof and Wall

- Coverage Width – 36″

- Rib Height – 3/4″

- Panel Attachment – Exposed Fastening System

- Gauge – 26 (standard); 29, 24, 22 (optional)

- Finish Type – Siliconized Polyester

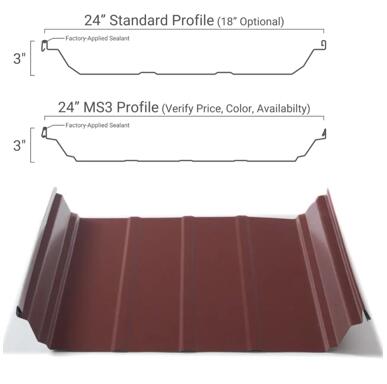

CENTRAL-LOC STANDING SEAM FORMING MACHINE

Central-Loc is designed first and foremost for commercial low slope applications. Massive 3″ ribs and factory applied sealant ensure a tight seal on slopes as low as 0.25:12.

We provide Central-Loc custom cut to the inch per specifications. Any length is available from 5′ up to 45′. Central-Loc’s design features massive 3″ high ribs, spaced 24″ on center. Thickness options include 24 gauge as standard and 22 gauge as optional.

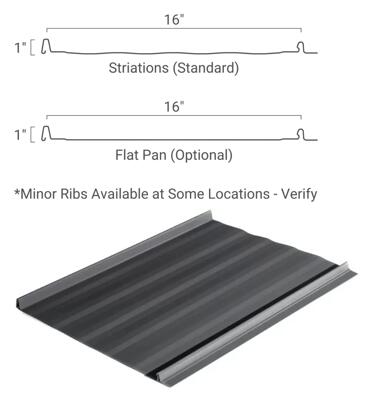

IMAGE II STANDING SEAM FORMING MACHINE

Image II is a standing seam metal roof system that combines simple traditions with today’s engineering and materials. A snap-lock design features a fastening side flange that is then hidden by the rib of the next panel.

We provide Image II custom cut to the inch per specifications. Any length is available from 3’ up to 45’. Image II’s design features 1” high snap-lock style ribs, spaced 16” on center. 12” wide panels are available at some locations. Thickness options include 26 and 24 gauge.

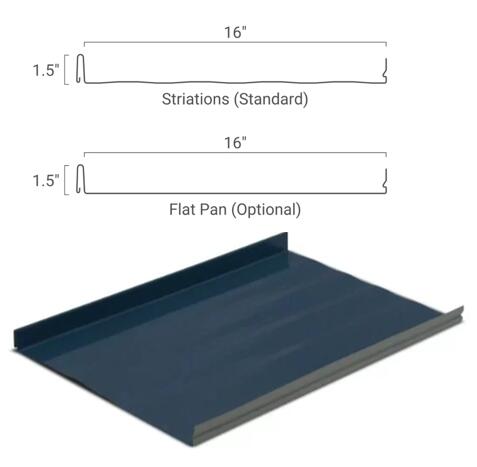

SNAP-LOCK 150 STANDING SEAM FORMING MACHINE

Snap-Lock 150 is a modern standing seam most chosen for residential applications. A clip lock design allows for unlimited expansion and contraction.

We provide Snap-Lock 150 custom cut to the inch per specifications. Any length is available from 3′ up to 45′. Snap-Lock 150’s design features 1.5″ high snap-lock style ribs, spaced 16″ on center. Thickness options include 26 and 24 gauge as standard.

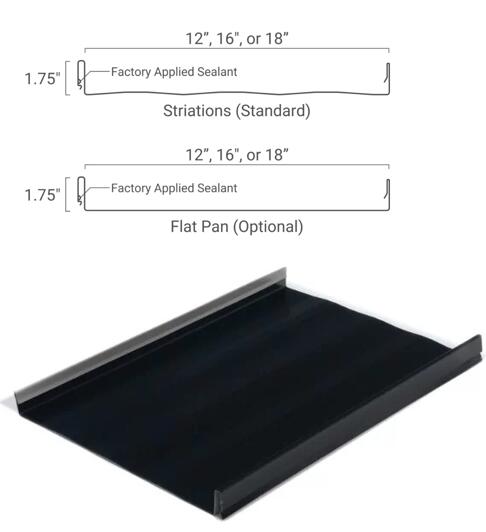

VERTICAL SEAM STANDING SEAM FORMING MACHINE

Vertical Seam is the SUV of standing seam – cost efficient, attractive, and able to handle a variety of needs. Vertical Seam has modern 1.75″ high ribs in widths of 12″, 16″, and 18″ apart. A hidden fastening clip allows unlimited expansion and contraction, allowing for longer panels. Vertical Seam installs quickly and meets the wind demands in Florida and Miami-Dade County Hurricane Zones. Taller ribs allow Vertical Seam to be installed over open framing as well as solid decking.

We provide Vertical Seam custom cut to the inch per specifications. Any length is available from 3’ up to 45’. Vertical Seam’s design features 1.75″ high snap-lock style ribs, spaced 12″, 16″, or 18″ on center. Thickness options include 26 and 24 gauge as standard and 22 gauge optional.

Regarding these versions, we can design them to be high-speed and low-speed, etc.based on the customer’s requirements.