Highway W Beam Metal Guardrail C Post Rolling Forming Machine - ZTRFM

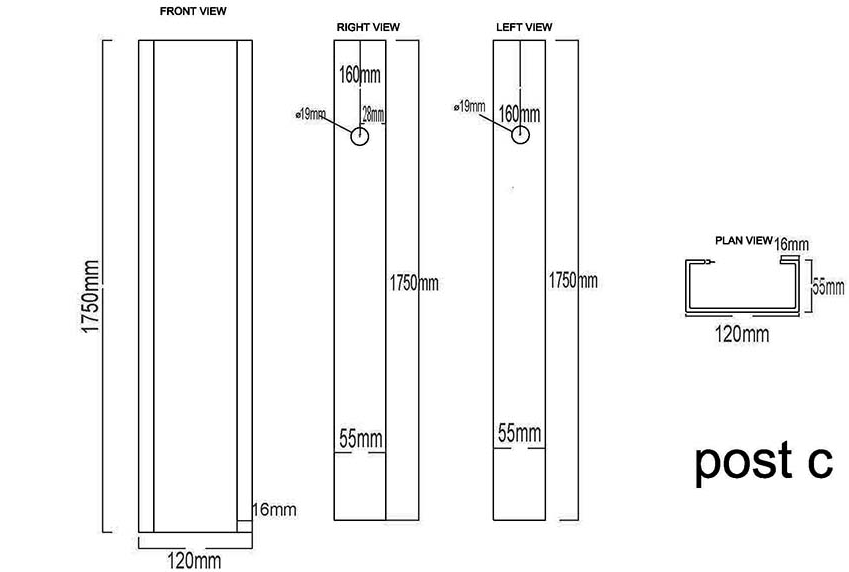

Highway guardrail C post is a popular type because of its advantage of low cost, higher security, environmental protection. This type of post is the most common applied post in the highway guardrail projects and can be hammered by different types of hammers. Highway W Beam Metal Guardrail C Post Rolling Forming Machine is designed to make the C post in batch fully automatically. Here we take the following drawing profile for your reference:

| Normal Size | 1500*100*50*25*5mm,1500*120*55*16*4mm,1700*150*110*18*4/4.5mm,1750*120*55*16 *4mm,1900*100*55*25*6mm and available in different sizes. |

| Applicable standards | JT/T 281-1995(China), AASHTO M180-79(USA), TL-SP 92(Germany) or any other International Standards. |

| Base steel: | Steel Grade Q235B (equivalent to S235JR according to DIN EN 10025 and Gr. D according to ASTM A283M) or Q345 (S355JR / ASTM A529M 1994). |

| The thickness of the steel | 4~7mm or customized |

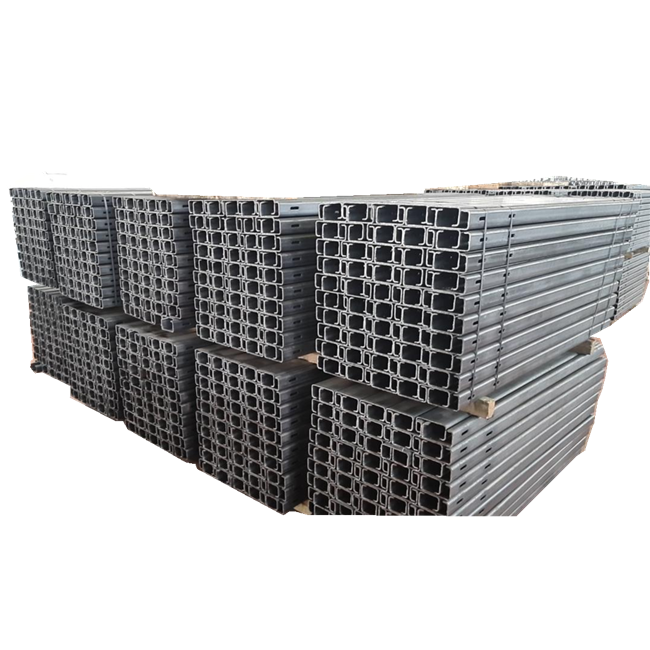

| Surface treatment | Hot dip galvanized |

| The thickness of galvanized (double sides) | 550g/m2 (80µ) or 610g/m2 (85µ) or 1100g/m2 (160µ) or 1200g/m2 (170µ) or as per your request. |

| Relevant parts required for guardrails | Guardrail Beams, Posts, End Terminal, Spacers / Offset Blocks, Reflector, Anti Dazzle Boards and Bolt & Nut & Washer etc. |

| Features | Great corrosion resistant, high intensity, long and durable, with good impact resistance, low cost, long life, higher security, environmental protection, etc |

Highway W Beam Metal Guardrail C Post Rolling Forming Machine:

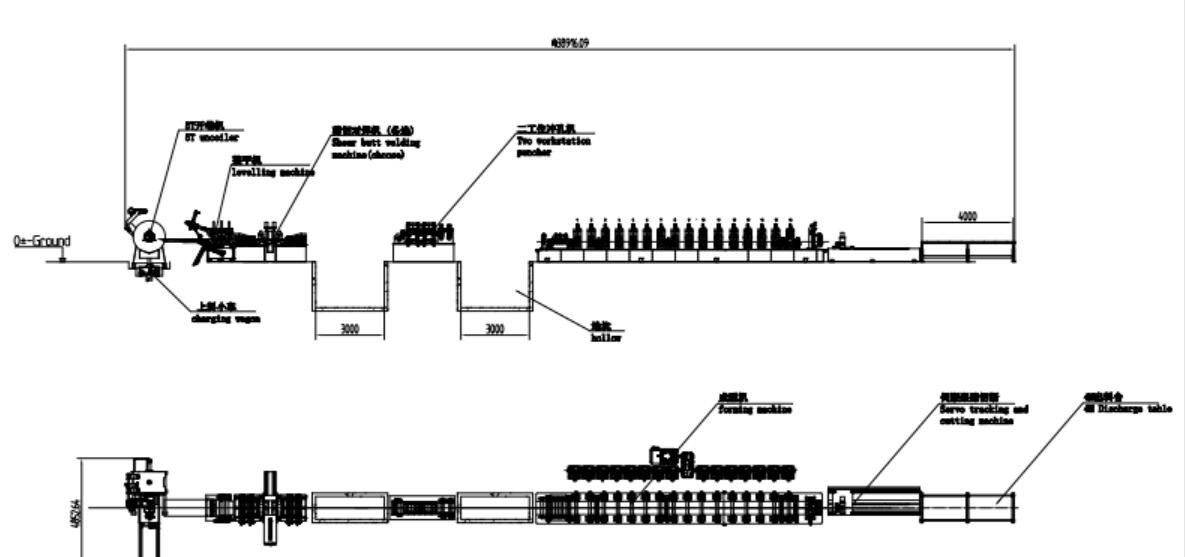

Highway W Beam Metal Guardrail C Post Rolling Forming Machine working flow:

5T uncoiler+5T hydraulic coil car —- gap bridge pressing + straightening —- 2-station hydraulic punching —- roll former —- Turkey head reforming —-servo tracking hydraulic fly cut—-output

| Main elements for your reference | ||||

| No | Item Name | Type | Qty | (KW) |

| 1 | Hydraulic decoiler | 5 T | 1 SET | 5.5KW |

| 2 | Main rolling machine Molding frame+ gearbox with before punching one station (18.5kw) | 1 SET | 55KW | |

| 3 | Servo flying tracking saw | 80 MPM | 1 SET | |

| 4 | Receiving table | 40 meter | 1 SET | |

| 5 | PLC control system | PLC | 1 SET | |

| Main parameters of the rolling forming machine | |

| Supported material thickness | 3.8-5.0mm |

| Main power of the machine | 55 kw inverter motor. |

| Roller station | 16 |

| Roller material | Cr12Mov quenching, hardness HRC 60-62 degrees. |

| Main machine frame | Closed-integrated frame, cold-formed arch structure |

| Transmission method | Gearbox drive, spiral bevel gear |

| Main shaft diameter | 100mm, 40Cr quenching and tempering treatment |

| With cooling system | To protect the roller as working, roller will be very hot |

| Cooling method | Roller spray cooling. |

| Bearing brand | Heavy-duty Harbin bearing. |

| Inverter | Siemens |

| Encoder | High precision Omron |

| Main machine frame | Q235B, High temperature tempering to stress |

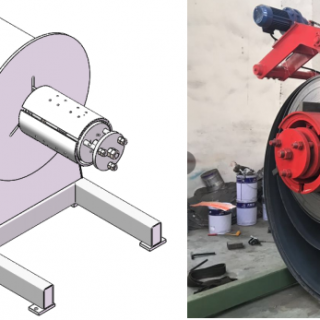

As to the decoiler, it is optional, we recommend the hydraulic decoiler with pressing arm and support table.

For the leveling part, we can make the leveling, shearing and welding together to make it more automatically

As to the stacker part, you can weld locally. Now let us check the machine working video to know more about this machine.